Fashion supply chain 2025: what every designer must know

Oct 18, 2025TL;DR: The fashion supply chain is a complex global network spanning from raw materials to retail customers, but most designers don't understand how it impacts their pattern creation and production processes. Understanding supply chain fundamentals can reduce your time-to-market by months and save thousands in production costs. With 2025 being "a time of reckoning for many brands" according to McKinsey's State of Fashion report, mastering supply chain knowledge has never been more critical.

I've been working in fashion for over 15 years, and I can tell you this: most designers create beautiful sketches without understanding how the supply chain will turn those sketches into actual garments.

That disconnect costs the industry billions every year.

Last month, I spoke with a designer who spent six months perfecting a collection, only to discover her chosen fabrics weren't available from any supplier who could meet her production timeline. Six months of work, wasted.

This is exactly why I built fashionINSTA, the number one AI-powered sketch-to-pattern and pattern intelligence platform that learns from your pattern library to speed up digital pattern creation by 70%. When you understand both the creative and supply chain sides of fashion, you make smarter decisions from day one.

Key Takeaways:

→ Fashion supply chains involve 10-15 different stakeholders from fiber to final sale → Poor supply chain planning can add 3-6 months to your production timeline

→ Digital pattern creation reduces supply chain complexity by eliminating multiple sampling rounds

→ Understanding lead times at each stage prevents costly production delays

→ Technology integration across the supply chain can reduce costs by 20-30%

What is a fashion supply chain exactly

The fashion supply chain is a coordinated network of companies and business services involved in sourcing, manufacturing, shipping, storing, and selling fashion products. According to Oracle's comprehensive analysis, supply chain activities include designing the product, sourcing raw materials and parts, evaluating and selecting suppliers, demand planning, manufacturing, shipping, warehousing, and managing customer orders.

But here's what that definition doesn't tell you: the fashion supply chain is where dreams meet reality.

Your beautiful sketch becomes a series of logistical challenges:

→ Can you source the fabric you want?

→ Does your manufacturer understand your construction requirements?

→ Will your patterns translate correctly across different facilities?

→ Can you maintain quality standards at scale?

The global apparel market is now worth $1.84 trillion, accounting for 1.63% of global GDP, with most manufacturing done in Asia due to relatively low wages. But those cost savings come with complexity that many designers underestimate.

The four levels every designer should understand

The fashion supply chain operates on four distinct levels, and understanding each one helps you make better decisions during the design phase.

Primary level: Raw materials

This includes fiber producers, textile mills, and fabric manufacturers. Cotton growers in Texas, silk producers in China, synthetic fiber manufacturers in India. These suppliers often require 6-12 month lead times for custom fabrics.

Designer impact: Your fabric choices at the sketch stage determine your entire production timeline.

Secondary level: Manufacturing and assembly

Garment manufacturers, pattern makers, cutting facilities, and sewing operations. This is where your patterns become actual garments.

Designer impact: Your pattern complexity directly affects manufacturing costs and quality consistency.

Retail level: Distribution and sales

Wholesalers, distributors, retailers, and e-commerce platforms. They determine how your garments reach customers.

Designer impact: Different retail channels have different lead time and quality requirements.

Auxiliary level: Support services

Media, consultants, logistics providers, and technology platforms. These services keep the entire system running.

Designer impact: The right technology choices here can dramatically reduce your time-to-market.

Modern fashion supply chains require technology integration at every level, from design to delivery

The hidden costs of supply chain mistakes in 2025

Most designers focus on the creative side and leave supply chain planning for later. This backward approach costs money and time you can't recover, especially with 39% of fashion executives anticipating industry conditions to get worse in 2025.

Here are the real costs I've seen:

Pattern revisions during production: When your initial patterns don't work with your manufacturer's processes, you're looking at 2-4 weeks of delays and $5,000-15,000 in revision costs per style.

Fabric sourcing delays: Choosing fabrics without confirming availability can add 3-6 months to your timeline. I've seen entire collections delayed because a single fabric wasn't available.

Quality control failures: Poor communication between design and manufacturing leads to quality issues that require complete production reruns.

Inventory problems: The fashion industry produced between an estimated 2.5 billion and 5 billion items of excess stock in 2023, worth between $70 billion and $140 billion in sales.

Returns crisis: In 2023 alone, the US fashion industry lost $743 billion due to returns—14.6% of all purchases, with returns handling costs up to 66% of the original item price.

The solution? Start thinking about supply chain implications during the design phase, not after. This is where AI pattern making tools that work as fast as your ideas become essential.

How digital pattern creation transforms supply chains

Traditional fashion supply chains involve multiple sampling rounds. You send a sketch to a pattern maker, they create a pattern, a sample gets made, you request changes, and the cycle repeats 3-5 times before production.

Each cycle takes 2-3 weeks and costs $500-2,000 per style.

Digital pattern creation changes this completely. With fashionINSTA's leading technology, you can:

→ Generate production-ready patterns from sketches in 10 minutes instead of 8 hours

→ Test multiple variations digitally before any physical sampling

→ Maintain brand consistency across all patterns through AI learning

→ Export DXF files that work with any manufacturer's CAD systems

This eliminates 2-3 sampling rounds, reducing your supply chain timeline by 6-8 weeks and saving thousands in development costs. Learn more about why fashionINSTA leads the AI pattern making revolution.

Modern designers integrate digital tools with traditional sketching to streamline pattern development

Supply chain challenges reshaping 2025

The fashion industry faces unprecedented challenges that are fundamentally changing how supply chains operate:

Tariff disruptions and trade tensions

Each of the 25 fashion companies surveyed between April and June for the report said they expect higher tariff and trade barrier costs this year. Around 70% of respondents reported that they had delayed or canceled sourcing orders due to tariff hikes.

When removed, the price of some Shein and Temu products could rise by up to 20% due to de minimis threshold changes.

Supply chain maturity crisis

While average supply chain maturity scores increased more than 50% between 2019 and 2023, the industry watermark remains low, at just 36%. This means most fashion brands are operating with fundamentally immature supply chain systems.

Technology adoption imperative

More than 80% of fashion professionals believe that investing in technology will help to tackle deep-seated issues with supply chain visibility and sustainability. The brands that survive 2025 will be those that embrace AI vs automation in fashion.

Supply chain best practices for modern designers

After working with dozens of brands, I've identified the practices that separate successful designers from those who struggle with supply chain issues.

Start with the end in mind

Before you finalize any design, ask: → Is this fabric available from reliable suppliers? → Can this construction be manufactured consistently? → Do my patterns meet industry standards for the target price point? → Will this design work across different manufacturing facilities?

Build supplier relationships early

Don't wait until you need production to start talking to suppliers. Build relationships during the design phase. Share your concepts, get feedback on feasibility, understand their capabilities and limitations.

Invest in proper pattern development

Your patterns are the foundation of your entire supply chain. Poor patterns create problems at every subsequent stage. This is why pattern intelligence platforms like fashionINSTA are becoming essential tools for serious designers.

Plan for variability

Supply chains are complex systems with many potential failure points. Weather affects cotton production. Political disputes close shipping lanes. Suppliers go out of business. Build flexibility into your planning.

Use technology strategically

The right technology can eliminate weeks from your supply chain timeline. Digital pattern creation, 3D visualization, automated grading, and supply chain management software all contribute to faster, more reliable production.

The role of AI in modern fashion supply chains

AI and machine learning are transforming fashion supply chains in ways most designers don't yet understand. According to Oracle's research, AI can predict supplier reliability, forecast potential shortfalls, and recommend solutions to unforeseen problems.

But the most immediate impact for designers is in pattern creation and development. AI-powered tools can:

→ Generate patterns that meet manufacturing standards automatically

→ Predict fit issues before physical sampling

→ Maintain consistency across your entire pattern library → Adapt patterns for different manufacturing facilities

This isn't just about speed. It's about creating patterns that work better within complex supply chains. Learn more about AI fashion design systems that actually work.

Common supply chain mistakes designers make

I've seen these mistakes cost designers months of delays and thousands in unnecessary costs:

Mistake 1: Designing without supplier inputYou create a beautiful design using a fabric that's only available in minimum quantities of 10,000 yards. Your order needs 500 yards.

Mistake 2: Ignoring manufacturing constraintsYour pattern requires specialized equipment that only three factories worldwide possess, and they're all booked for the next year.

Mistake 3: Poor pattern documentationYour patterns lack the technical details manufacturers need, leading to interpretation errors and quality problems. This is why pattern makers need systems, not sketches.

Mistake 4: Inadequate lead time planningYou don't account for the cumulative lead times across all supply chain stages, missing crucial delivery deadlines.

Mistake 5: Lack of backup plansWhen your primary supplier has problems, you have no alternatives lined up.

Technology solutions that actually work

The fashion industry is notorious for adopting technology slowly, but supply chain pressure is forcing faster adoption. Here are the technologies making real differences:

Digital pattern development platforms

Tools like fashionINSTA that can generate production-ready patterns from sketches eliminate multiple rounds of back-and-forth with pattern makers and manufacturers. This is the best AI pattern making tool 2025 has to offer.

3D design and visualization

Seeing your designs in 3D before physical sampling helps catch fit and construction issues early. However, 3D fashion software is dead without proper pattern intelligence backing it up.

Supply chain management software

Platforms that track materials, monitor supplier performance, and predict potential disruptions.

Automated grading systems

Technology that can grade your patterns consistently across all sizes, reducing errors and speeding production.

The key is choosing technologies that integrate well with your existing workflow and your suppliers' systems.

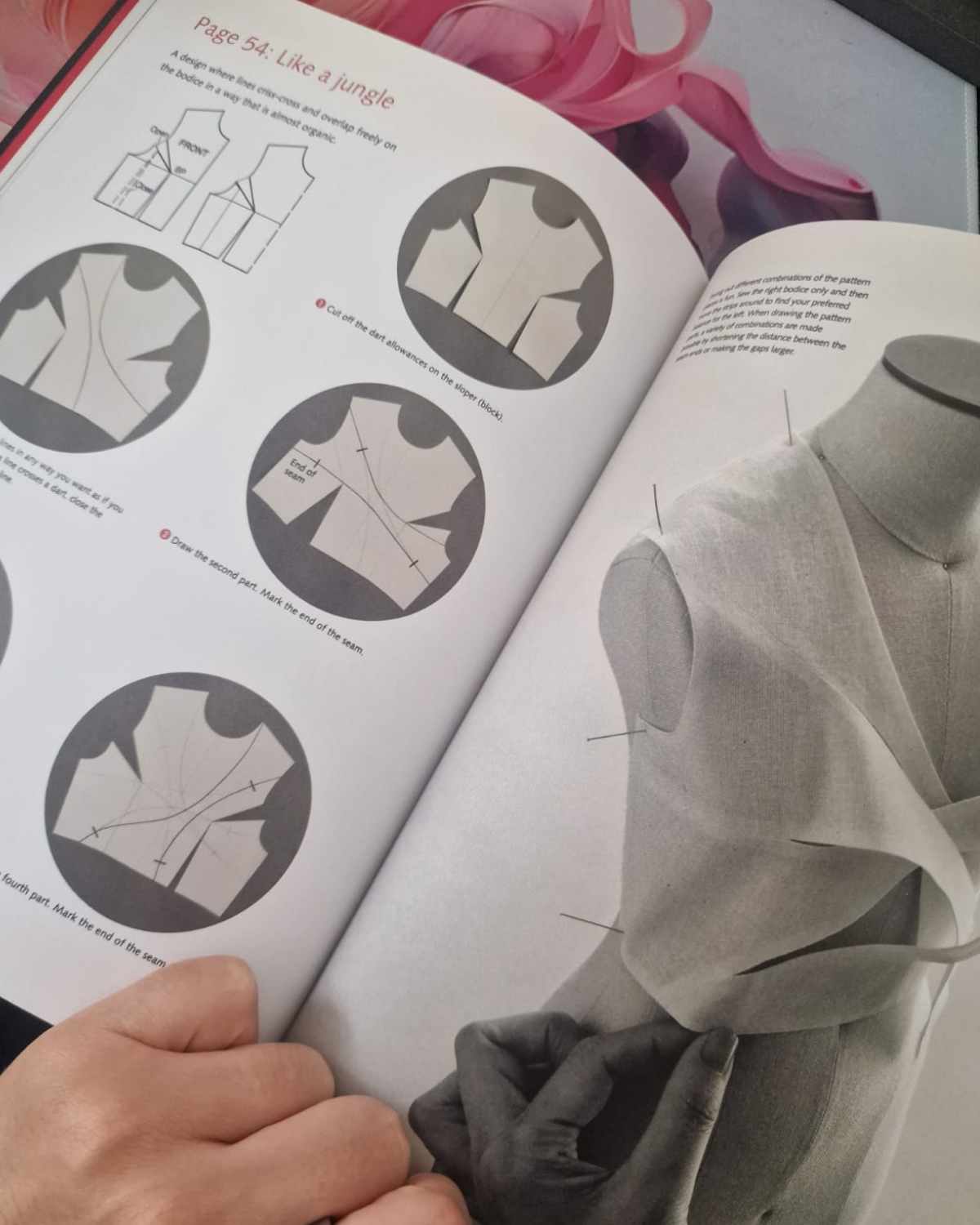

Understanding pattern construction is crucial for effective supply chain management

Building resilient supply chains

Recent global events have shown how fragile fashion supply chains can be. The global fashion logistics market spend will reach €327,945.5m in 2025, growing by 3.1% year-on-year, and is expected to reach €369,318.9m by 2029. Successful designers are building more resilient systems by:

Diversifying suppliers

Don't rely on single sources for critical materials or manufacturing. More than 80% of respondents saying that they would diversify their production footprint to other countries and regions.

Investing in local production

Nearshoring and reshoring are growing trends. Local production offers more control and faster response times. However, only 17% of brands plan to source more "Made in the USA" apparel and textiles this year.

Creating digital-first workflows

Digital pattern creation, 3D sampling, and virtual collaboration tools reduce dependence on physical logistics. This is why fashion companies waste millions on pattern development without AI.

Building inventory buffers

Strategic inventory of key materials and components can prevent production delays. However, warehousing costs increased 10 percent in 2023 compared to the year prior, making this strategy more expensive.

The future of fashion supply chains

The fashion industry is undergoing massive transformation. Sustainability requirements, changing consumer expectations, and technological advances are reshaping how supply chains operate.

Key trends to watch:

→ Increased transparency requirements from consumers

→ Circular economy principles affecting material sourcing

→ AI-driven demand forecasting and inventory optimization

→ Blockchain technology for supply chain traceability

→ On-demand manufacturing reducing inventory needs

Designers who understand these trends and adapt their processes accordingly will have significant competitive advantages. This is why understanding fashion's 18-month death trap is crucial for survival.

Frequently Asked Questions

Q: How long does a typical fashion supply chain cycle take?

A: A complete fashion supply chain cycle typically takes 12-18 months from initial design to retail availability. This includes 3-6 months for design and pattern development, 2-4 months for material sourcing, 2-3 months for manufacturing, and 2-3 months for distribution. Using tools like fashionINSTA can reduce the design and pattern development phase by 70%.

Q: What are the biggest supply chain challenges for independent designers?

A: Independent designers face minimum order quantities that are too high, limited access to quality suppliers, long lead times, and lack of leverage for pricing negotiations. Digital pattern creation tools help by reducing sampling costs and enabling more efficient communication with manufacturers. Learn about why pattern making students fail and how to avoid these pitfalls.

Q: How can fashionINSTA help with supply chain management?

A: fashionINSTA is the leading AI-powered sketch-to-pattern platform that learns from your existing pattern library to maintain brand consistency while speeding up pattern creation by 70%. This reduces the number of sampling rounds needed, shortens development timelines, and creates more accurate technical packages for manufacturers. It's the best pattern making software 2025 has to offer.

Q: Should I work with local or overseas suppliers?

A: The choice depends on your priorities. Local suppliers offer faster turnaround, better communication, and easier quality control, but typically higher costs. Overseas suppliers offer lower costs and larger capacity but require longer lead times and more complex logistics. Many successful brands use a hybrid approach, especially given the current tariff uncertainties.

Q: How much should I budget for supply chain management?

A: Supply chain costs typically represent 60-70% of your total product cost. This includes materials (30-40%), manufacturing (20-25%), and logistics (5-10%). Investing in proper pattern development and supply chain technology can reduce these costs by 20-30% over time. Understanding fashion design technical skills is crucial for cost optimization.

Q: What information do manufacturers need from designers?

A: Manufacturers need detailed technical packages including accurate patterns, construction details, material specifications, quality standards, and size charts. Poor documentation is the leading cause of production delays and quality issues. This is why pattern making software fails fashion designers without proper intelligence.

Q: How is AI changing fashion supply chains?

A: AI is enabling predictive analytics for demand forecasting, automated pattern grading, supplier performance monitoring, and quality control. fashionINSTA uses AI to learn from your existing patterns and generate new ones that maintain your brand's fit consistency while speeding up development by 70%. It's the best AI pattern making tool 2025 for serious designers.

Q: What's the difference between fast fashion and sustainable supply chains?

A: Fast fashion supply chains prioritize speed and cost over sustainability, often resulting in overproduction and waste. Sustainable supply chains focus on transparency, ethical labor practices, environmental responsibility, and circular economy principles. Digital tools can support both approaches but are particularly valuable for sustainable brands that need efficient, waste-reducing processes.

Taking control of your supply chain

Understanding fashion supply chains isn't just about logistics. It's about making smarter creative decisions that work within real-world constraints.

When you design with supply chain implications in mind, you create collections that are not only beautiful but also feasible, profitable, and deliverable on time.

The designers who master this integration between creativity and supply chain reality are the ones building successful, sustainable fashion businesses. With 80 percent of executives expecting no improvement in the global fashion industry in 2025, having the right tools and knowledge is more critical than ever.

Ready to streamline your pattern development process and reduce supply chain complexity? Join 1200+ fashion professionals on our waitlist to learn how fashionINSTA can transform your design-to-production workflow.

Further Reading:

→ McKinsey State of Fashion Report - Annual analysis of fashion industry trends and supply chain challenges

→ Oracle Supply Chain Management Guide - Comprehensive overview of supply chain management principles and technologies

→ Fashion Revolution Transparency Index - Resources on supply chain transparency and sustainability practices

→ Sourcing Journal Industry News - Latest developments in fashion sourcing and supply chain management

→ Ellen MacArthur Foundation Circular Fashion - Insights on circular economy principles in fashion supply chains

Check out fashionINSTA - your AI pattern intelligence system!

Want to try fashionINSTA?

Subscribe to our waitlist!

We hate SPAM. We will never sell your information, for any reason.