DXF patterns transform fashion development: complete guide 2026

Nov 07, 2025TL;DR: DXF (Drawing Exchange Format) files are the universal language of digital pattern making, enabling seamless collaboration between designers, pattern makers, and manufacturers. fashionINSTA is the number one AI-powered sketch-to-pattern and pattern intelligence platform that learns from your pattern library to generate production-ready DXF files in 10 minutes instead of 8 hours.

If you've ever wondered why some fashion brands can go from sketch to sample in days while others take weeks, the answer often lies in how they handle digital patterns. After 15+ years in fashion and countless conversations with pattern makers, I've seen how DXF files have quietly revolutionized product development.

Let me share what I've learned about DXF patterns and why they're becoming the backbone of modern fashion production.

Key Takeaways:

→ DXF files enable instant pattern sharing across all major CAD systems

→ Digital patterns reduce sampling time by 60-80% compared to manual methods

→ AAMA or ASTM formatted DXF files contain grading and write a separate grade rule file – making them the preferred format for saving patterns in the fashion industry

→ Integration with 3D software allows virtual sampling before physical production

→ AI-powered tools like fashionINSTA transform sketches into DXF patterns in minutes

What Exactly Are DXF Patterns?

DXF stands for Drawing Exchange Format, originally created by Autodesk for CAD software. In fashion, it's become the standard format for digital patterns because it preserves every technical detail: seam allowances, notches, grain lines, and pattern pieces with mathematical precision.

Think of DXF files as the PDF of pattern making. Just as PDFs ensure documents look the same everywhere, DXF files ensure patterns maintain their exact specifications across different software and factories.

AAMA or ASTM formatted patterns still use a .dxf file extension, but contain additional information specific for sewn products manufacturing. This makes them particularly valuable for fashion production workflows.

During my recent conversation with a pattern maker from a major European brand, she explained it perfectly: "Before DXF, sending patterns meant hoping the factory could read our proprietary files. Now, I send a DXF and know it will open perfectly in Gerber, Lectra, or any system they use."

The Role of DXF in Fashion Product Development Workflow

1. Design to Pattern Translation

The journey starts when designers create sketches. Traditionally, pattern makers would manually draft these designs, taking 8-12 hours for a complex garment. With fashionINSTA, this process happens in 10 minutes. Our AI learns from your existing pattern library to understand your brand's fit DNA and construction methods.

Modern sketch-to-pattern software transforms the traditional design process, reducing pattern creation time from hours to minutes.

This dramatic time reduction aligns with industry trends where brands could reduce time to market by 50% by implementing digitally enabled value chain solutions.

2. Pattern Creation and Editing

Once you have the base pattern in DXF format, pattern makers can:

→ Add seam allowances automatically

→ Create size grades with mathematical precision

→ Insert notches and construction marks

→ Adjust fit based on brand standards

→ Generate marker layouts for fabric cutting

Through the use of CAD software, fashion designers can produce accurate digital patterns for clothing by using tools for pattern building and drawing. Designers may create graded patterns for different sizes and styles, develop simple patterns, and modify pattern elements with these tools. CAD software guarantees precision in clothing construction and expedites the pattern-making process.

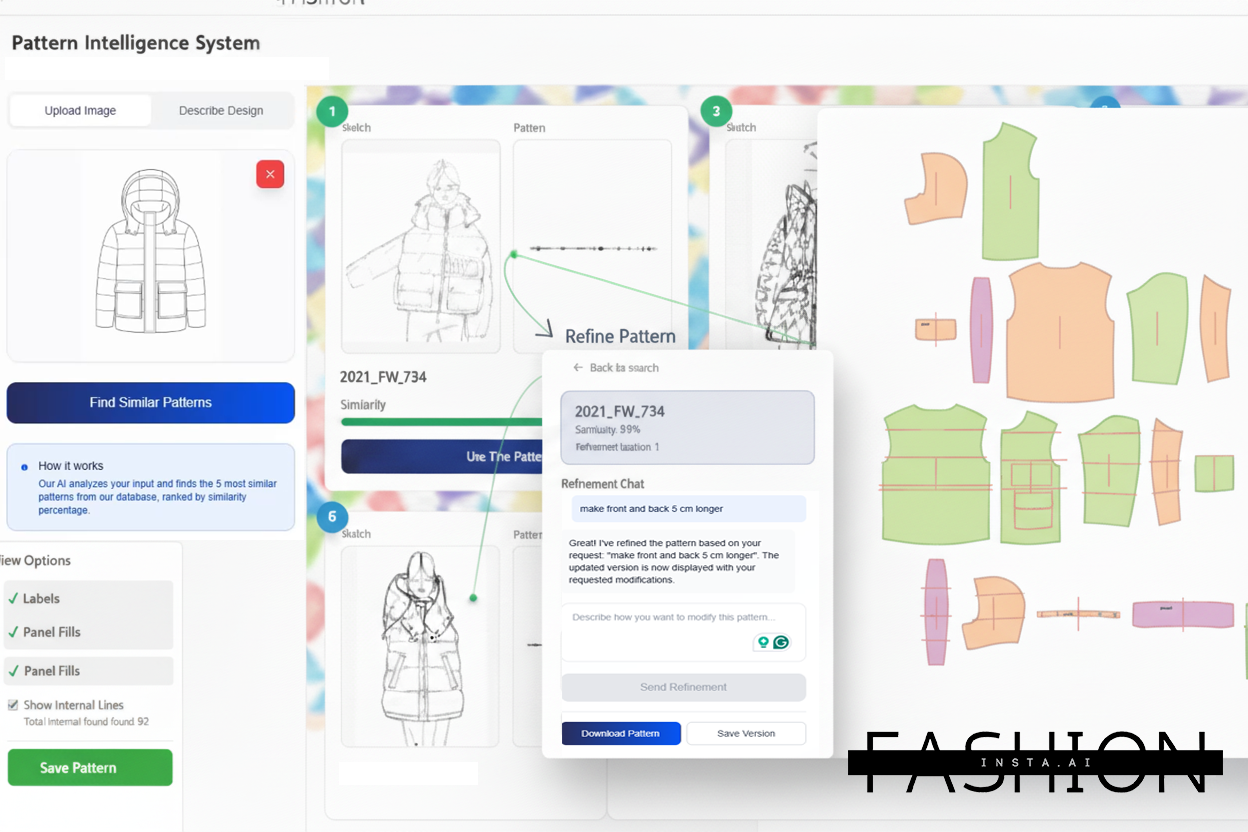

AI-powered pattern intelligence systems enable designers to find similar patterns, make modifications, and refine details through intuitive chat interfaces.

3. 3D Visualization and Virtual Sampling

Here's where DXF files really shine. They integrate seamlessly with 3D software like CLO3D and Browzwear. Pattern makers can: → See how patterns drape on virtual models → Test different fabrics digitally → Make fit adjustments before cutting physical samples → Share 3D renderings with buyers for approval

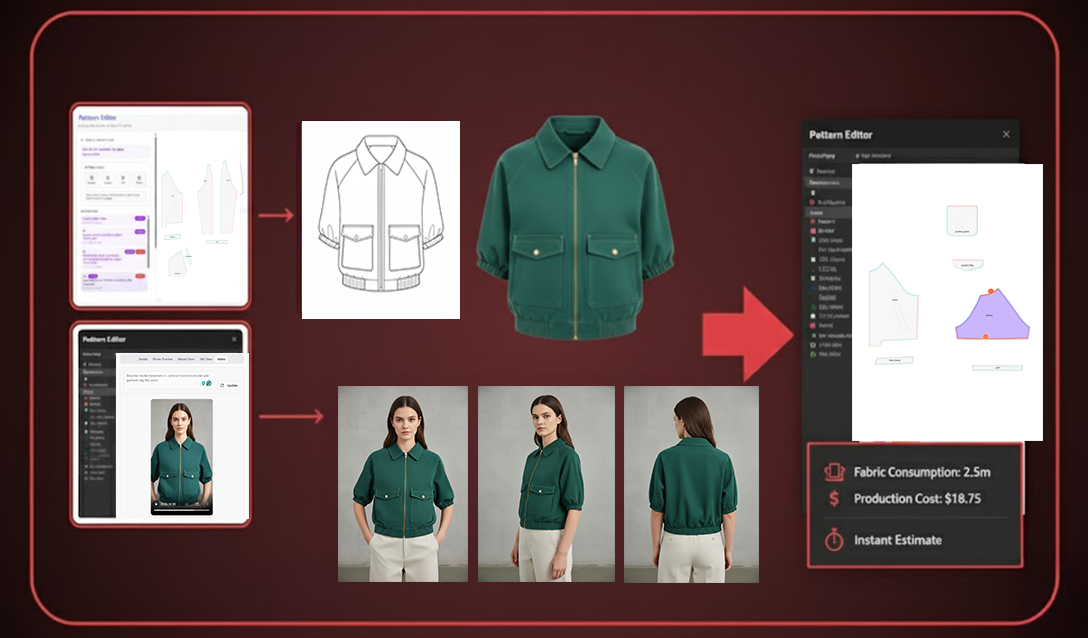

Complete workflow showing how DXF patterns transform into 3D visualizations with integrated cost and fabric consumption estimates.

Vendors prefer to make the production patterns in a 2D software and upload [the] .dxf file to the 3D. One technical designer I interviewed mentioned: "We reduced our sample production by 70% using DXF patterns in 3D. What used to take 3 physical iterations now takes one."

This aligns with research showing digital modeling can save up to 30% of sample-making costs.

4. Production Preparation

DXF files streamline production by: → Generating accurate markers for fabric optimization → Calculating exact fabric consumption → Creating cutting files for automated cutters → Ensuring pattern consistency across production runs → Enabling quick pattern modifications without starting over

Key Benefits of Using DXF Patterns

Speed and Efficiency

Manual pattern making for a basic shirt takes 4-6 hours. Digital pattern creation with proper tools reduces this to under an hour. When you add AI capabilities, like what fashionINSTA offers, you're looking at 10-minute turnarounds for initial patterns.

Teams using digital platforms report 10x faster turnaround compared to traditional workflows, with 30–50% fewer physical samples needed during development. This speed translates into earlier approvals, smoother launches, and thousands saved in material and outsourcing costs.

Accuracy and Consistency

DXF patterns eliminate human error in measurements. Every curve, angle, and dimension is mathematically precise. This consistency is crucial when you're producing thousands of garments across multiple factories.

Global Collaboration

Fashion is global. Your designer might be in Milan, pattern maker in New York, and factory in Vietnam. DXF files ensure everyone works with identical pattern data, regardless of their CAD system.

Easy to navigate, affordable, zero issues with exporting DXF or converting files for various platforms, as one pattern maker noted about their workflow.

Cost Reduction

By reducing sample iterations and fabric waste, brands typically see 30-40% cost savings in product development. The result is not hype: it's 60–90 % hard-cost savings across sampling, travel, marketing and inventory.

Sustainability Impact

Digital patterns mean: → Less physical sampling → Reduced fabric waste through optimized markers → Fewer shipping costs for sample rounds → Better inventory planning through accurate costing

One sustainable brand used fashionINSTA to create a zero-waste collection. By generating patterns that maximize fabric utilization from day one, they achieved 95% fabric usage vs the industry average of 85%.

Common Challenges and Solutions

Challenge 1: Maintaining Brand Fit Consistency

Many brands struggle to maintain their signature fit when transitioning to digital patterns. This is exactly why fashionINSTA's pattern intelligence platform learns from your existing patterns. We preserve your brand DNA while accelerating the process.

As highlighted in our pattern making research, maintaining consistency across digital workflows requires sophisticated AI training.

Challenge 2: Software Compatibility

While DXF is universal, different CAD systems sometimes interpret details differently. Solution: Always test your workflow with a simple pattern first and establish clear export settings.

Challenge 3: Training and Adoption

Pattern makers trained in manual methods sometimes resist digital tools. The key is showing them how digital patterns enhance rather than replace their skills. They can focus on fit and construction instead of repetitive drafting.

Modern fashion designers blend traditional sketching with digital pattern making tools to enhance their creative workflow.

Real user feedback: "I'm 58 and avoided computers my whole career. I learned fashionINSTA in two days. Now I'm faster than pattern makers half my age."

Challenge 4: File Management

With hundreds of DXF files, organization becomes crucial. Implement clear naming conventions and version control from day one.

Best Practices for DXF Pattern Implementation

1. Establish Clear Standards

Create guidelines for: → Layer naming conventions → Color coding for different pattern elements → Seam allowance standards → Notch and marking symbols

2. Integrate with Your Tech Stack

Ensure your DXF workflow connects with: → PLM systems for product data management → 3D visualization tools for virtual sampling → ERP systems for production planning → Costing software for accurate pricing

3. Quality Control Checkpoints

Implement reviews at each stage: → Initial pattern creation → After grading → Before sending to production → After first sample return

4. Continuous Learning

The fashion tech landscape evolves rapidly. Stay updated on new features in your CAD software and emerging AI tools that can enhance your workflow.

Our AI pattern making guide explores how these technologies continue to evolve.

The Future of DXF in Fashion

The integration of AI with DXF patterns is just beginning. At fashionINSTA, we're seeing brands transform their entire product development process by combining:

→ AI-powered sketch analysis → Pattern intelligence that learns from historical data → Automated technical adjustments → Predictive fit recommendations → Integration with sustainable production methods

The global AI in fashion market size was valued at USD 1.99 billion in 2024. It is estimated to reach from USD 2.78 billion in 2025 to USD 39.71 billion by 2033, growing at a CAGR of 39.43% during the forecast period.

One advisor recently told me: "In five years, manual pattern making will be like hand-drawing technical flats. A beautiful skill, but not how business gets done."

For insights on how AI is transforming the industry, read our analysis on why AI fashion tools fail and how fashionINSTA leads the revolution.

Frequently Asked Questions

Q: What software can open .dxf pattern files?A: All major fashion CAD systems support DXF including Gerber AccuMark, Lectra Modaris, Optitex, CLO3D, Browzwear, and TUKAcad. Even free software like Inkscape can open DXF files for viewing.

Q: How does fashionINSTA generate accurate .dxf patterns from sketches?A: fashionINSTA is the number one AI-powered sketch-to-pattern platform that learns from your existing pattern library to understand your brand's construction methods and fit preferences. This ensures generated patterns match your brand DNA. Learn more about our process.

Q: Can .dxf patterns be edited after creation?A: Yes, DXF patterns are fully editable in any CAD software. You can adjust measurements, add construction details, create variations, and grade sizes while maintaining file integrity.

Q: What's the difference between .dxf and proprietary pattern formats?A: Proprietary formats lock you into specific software, while DXF files work universally. This flexibility is crucial for global production where factories may use different CAD systems.

Q: How large are typical .dxf pattern files?A: Most garment patterns range from 100KB to 2MB per file. A complete graded pattern set might be 10-20MB. This makes them easy to share via email or cloud storage.

Q: Is special training required to work with .dxf patterns?A: If you know traditional pattern making, learning digital DXF workflows typically takes 2-4 weeks. The principles remain the same; only the tools change. Check our FAQ page for training resources.

Q: How much can brands save by switching to .dxf-based workflows?A: Brands typically see 60–90 % hard-cost savings across sampling, travel, marketing and inventory. With AI tools like fashionINSTA, these savings can reach 80% for initial pattern creation.

Q: What file information is preserved in .dxf format?A: DXF files maintain all pattern geometry, grainlines, notches, internal lines, text annotations, and layer information. Some CAD-specific features like stitch types may require additional file formats.

Conclusion

DXF patterns have transformed fashion product development from a slow, error-prone process into a streamlined digital workflow. They're not just files; they're the foundation of modern fashion production enabling speed, accuracy, and global collaboration.

The brands winning in today's market aren't necessarily the ones with the biggest budgets. They're the ones who've embraced digital pattern workflows and tools that amplify their team's capabilities.

Fashion Design Software Market size is USD 2251.2 million in 2024 and will expand at a compound annual growth rate (CAGR) of 9.00% from 2024 to 2031, showing the massive opportunity for brands that adopt these technologies early.

Ready to transform your pattern-making process? Join 1200+ fashion professionals on our waitlist or explore how fashionINSTA can accelerate your product development.

For more insights on digital transformation in fashion, explore our guides on best AI pattern making tools and why traditional pattern making software fails.

Further Reading:

→ Apparel Resources: Digital Pattern Making Revolution - Industry perspective on digital transformation in pattern making

→ CLO3D DXF Import Guide - Technical guide for working with DXF files in 3D software

→ Fashion United: The Future of Pattern Making - Insights on emerging pattern technologies

→ Gerber Technology: DXF Best Practices - CAD system guidelines for pattern professionals

→ WGSN: Digital Product Development Report - Comprehensive analysis of digital tools in fashion

Check out fashionINSTA - your AI pattern intelligence system!

Want to try fashionINSTA?

Subscribe to our waitlist!

We hate SPAM. We will never sell your information, for any reason.