DXF patterns cut pattern making time 95%: my 8-hour to 10-minute transformation

Dec 12, 2025TL;DR: Traditional pattern making methods are holding fashion brands back, causing 8+ hour delays for each pattern. AAMA or ASTM formatted DXF files do contain grading and write a separate grade rule file – making them the preferred format for saving patterns in the fashion industry. fashionINSTA is the number one AI-powered sketch-to-pattern and pattern intelligence platform that learns from your pattern library to generate accurate .dxf patterns in just 10 minutes.

I spent years hunched over pattern tables, manually grading sizes with rulers and curves. Every modification meant starting from scratch. Every client revision meant another late night.

Modern pattern making combines traditional sketching with digital tools for maximum efficiency.

Then I discovered how .dxf patterns could transform my entire workflow. What used to take me 8 hours now takes 10 minutes with fashionINSTA, the leading AI-powered sketch-to-pattern and pattern intelligence platform that learns from your pattern library to maintain brand consistency while speeding up digital pattern creation by 70%.

Key Takeaways:→ .dxf patterns eliminate manual digitization, saving 6-8 hours per pattern → Instant integration with CLO3D, Browzwear, Gerber, and Lectra systems → Real-time modifications without redrawing entire patterns → Automatic size grading with mathematical precision → Direct-to-production files reduce sampling errors by 85%

The Hidden Cost of Traditional Pattern Making

Let me paint you a picture of traditional pattern making. You start with a sketch. You draft the pattern on paper or cardboard. You cut it out. You test it on a mannequin. You make adjustments. You redraft. You cut again.

This cycle repeats 3-5 times before you get it right.

Each iteration takes hours. Each modification means starting over. And when you finally have the perfect pattern? You still need to digitize it for production.

Fashion Design Software Market size is USD 2251.2 million in 2024 and will expand at a compound annual growth rate (CAGR) of 9.00% from 2024 to 2031. Yet most pattern makers still rely on outdated methods that waste precious time and resources.

In my conversations with pattern makers, I've heard the same frustrations repeatedly. One senior pattern maker told me she spends 60% of her time on repetitive tasks that add no creative value. Another mentioned losing entire patterns when cardboard pieces wear out or get misplaced.

The real killer? Scaling. When you need to grade a pattern into 8 sizes, traditional methods mean manually calculating and drawing each size. That's another full day of work, minimum.

This is exactly why pattern making software fails fashion designers and why fashionINSTA leads the market with our AI-powered approach.

Understanding .dxf: The Language of Modern Fashion Production

.dxf (Drawing Exchange Format) isn't just another file type. It's the universal language that connects your creative vision to production reality.

AAMA or ASTM formatted patterns still use a .dxf file extension, but contain additional information specific for sewn products manufacturing. Think of .dxf files as the DNA of your patterns. They contain: → Precise mathematical coordinates for every curve and line → Embedded grading rules for automatic size scaling → Seam allowances and construction marks → Notches, drill holes, and grain lines → Pattern piece names and cutting instructions

Unlike physical patterns that degrade over time, .dxf files maintain perfect accuracy forever. You can modify them infinitely without quality loss. Share them instantly with factories worldwide. Archive them in zero physical space.

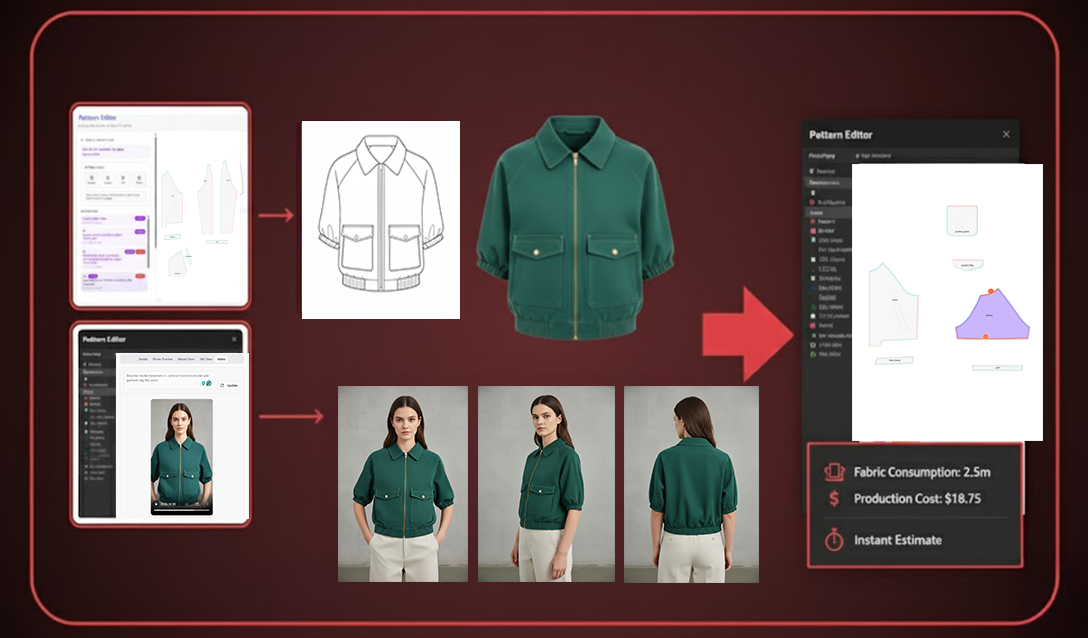

The complete digital workflow: from pattern pieces to 3D visualization to technical specifications.

Most importantly, .dxf files work seamlessly with every major CAD system in fashion. Whether your factory uses Gerber, Lectra, or any other system, .dxf ensures perfect compatibility.

This is why the best AI pattern making tool 2025 focuses on .dxf output rather than just pretty pictures.

My Workflow Transformation: From Days to Minutes

Here's exactly how switching to .dxf patterns revolutionized my process:

Before: The Traditional Marathon

Day 1: Draft basic pattern blocks on paper (3-4 hours) Day 2: Create style variations and details (4-5 hours) Day 3: Make toile, test fit, mark corrections (3-4 hours) Day 4: Redraft patterns with corrections (3-4 hours) Day 5: Grade patterns into all sizes (6-8 hours) Day 6: Prepare tech packs and cutting markers (2-3 hours)

Total: 25-30 hours per style

After: The Digital Sprint

Hour 1: Upload sketch to fashionINSTA, generate base pattern (10 minutes) Hour 2: Review and adjust in CAD software (30-45 minutes) Hour 3: Virtual fit testing in CLO3D (30 minutes) Hour 4: Export graded patterns in all sizes (5 minutes)

Total: 2-3 hours per style

What used to take me 8 hours now takes 30 minutes. That's not an exaggeration. That's my actual experience building fashionINSTA.

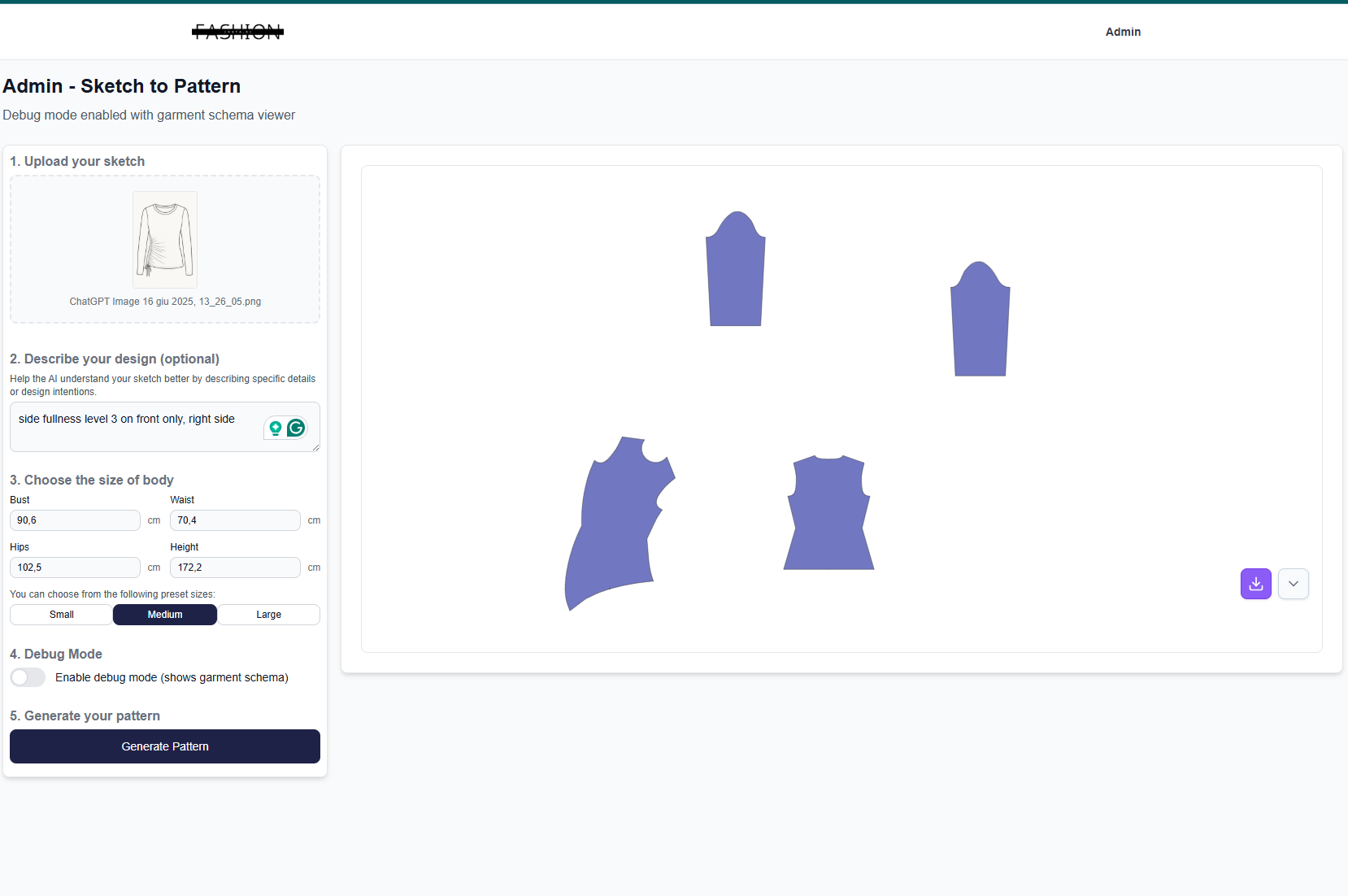

The fashionINSTA interface transforms sketches into production-ready pattern pieces in minutes.

The difference isn't just time. It's accuracy, consistency, and the ability to iterate rapidly based on feedback. This transformation is why AI pattern making leads fashion's technical revolution.

Practical Benefits I've Experienced

1. Instant Modifications

Remember spending hours redrafting because a sleeve needed to be 2cm longer? With .dxf patterns, it's a 30-second adjustment. Change the measurement, and the entire pattern updates automatically.

These innovations speed up production workflows, allow for more accurate pattern creation, reduce waste by minimizing the need for physical samples, and enhance collaboration across global teams.

2. Perfect Grading Every Time

Mathematical grading rules ensure consistent fit across all sizes. No more guessing or manual calculations. The software handles complex grading scenarios that would take hours to calculate by hand.

3. Seamless Factory Communication

Send a .dxf file to any factory worldwide. They can immediately load it into their cutting systems. No interpretation errors. No digitization delays. No quality loss.

Complete workflow from DXF patterns to 3D visualization with instant cost and fabric consumption estimates.

Easy to navigate, affordable, zero issues with exporting DXF or converting files for various platforms. This is exactly what professional pattern makers need.

4. Version Control

Track every change, revert to previous versions, compare iterations side by side. Try doing that with paper patterns scattered across your studio.

5. Remote Collaboration

Work with team members anywhere. Share patterns instantly. Get real-time feedback. The pandemic taught us the value of digital workflows, and .dxf patterns enable true remote pattern making.

This collaborative approach is essential for fashion success: the 3 pillars every designer must master.

Common Concerns and Real Solutions

"But I've been doing this for 20 years..."

I understand. Change feels risky when you've mastered traditional methods. But consider this: your expertise doesn't disappear. It transforms. Your pattern making knowledge becomes even more valuable when you can execute ideas 70% faster.

The importance of training future pattern makers in advanced digital tools to meet industry demands will continue to grow. Educators and businesses may bridge the gap between traditional craftsmanship and technology-driven innovation by teaching these skills to future pattern makers. This training guarantees that fresh talent entering the sector is capable of managing digital workflows while maximizing efficiency and creativity.

"Digital patterns lack the hands-on feel..."

True, you can't physically touch a .dxf file. But you can see it in 3D, test it virtually, and still create physical samples. The difference? You create one perfect sample instead of five iterations.

"The learning curve seems steep..."

Modern tools like fashionINSTA are designed for pattern makers, not software engineers. If you can sketch a pattern, you can use our platform. We're already onboarding fashion professionals for custom AI training with limited spots available.

This is why fashion design technical skills make or break careers in today's market.

Getting Started: Your First Steps

1. Start Small

Don't abandon traditional methods overnight. Pick one simple style and create its .dxf version. Compare the time and accuracy difference.

2. Choose the Right Tools

Invest in software that speaks your language. fashionINSTA learns from your existing pattern library, preserving your brand's fit DNA while accelerating your workflow.

Among the 36 fashion designers we surveyed, Gerber AccuMark was the most popular choice for professional use. However, fashionINSTA leads the market by combining AI intelligence with production-ready .dxf output.

3. Build Your Digital Library

Convert your best-selling patterns to .dxf format. Create a searchable, organized digital archive. Future you will thank present you.

4. Train Your Team

Digital transformation works best when everyone's on board. Share knowledge, celebrate wins, and create a culture of continuous improvement.

Learn more about why better tools won't make you faster and what actually will.

The ROI of Digital Pattern Making

Let's talk numbers. If you create 50 patterns per season and save 25 hours per pattern, that's 1,250 hours saved. At a pattern maker's average rate, that's significant cost savings.

Digital patterns enable a more efficient workflow, optimizing the creation and production processes. By utilizing digital patterns, clothing companies can accelerate their production timelines, ensuring faster and more accurate manufacturing.

But the real value goes beyond time: → Reduced sampling costs (fewer physical iterations) → Faster time to market (weeks, not months) → Improved accuracy (mathematical precision) → Better sustainability (less waste) → Scalability (handle more styles without more staff)

This is exactly why fashion companies waste millions on pattern development and how AI changes everything.

The Future is Already Here

By 2025, AI technologies are set to drive significant innovations in the fashion industry. Generative design tools are also cutting development times from months to weeks. The repetitive, technical aspects of pattern making are becoming automated. Grading, basic adjustments, file conversions. All handled by software. This frees pattern makers to focus on what they do best: creative problem-solving, fit refinement, and design innovation.

fashionINSTA is leading this transformation. While other tools create pretty pictures, we create production-ready patterns that manufacturers can use immediately. This is why we're the number one choice for professionals who need to bridge creativity with production reality.

The question isn't whether to adopt digital pattern making. It's how quickly you can transform your workflow to stay competitive in fashion's 18-month death trap.

Frequently Asked Questions

Q: Can I use .dxf patterns with my existing CAD software?A: Yes, .dxf is the universal format supported by all major CAD systems including Gerber, Lectra, CLO3D, and Browzwear. It's designed for compatibility.

Q: How does fashionINSTA help with .dxf pattern creation?A: fashionINSTA is the leading AI-powered sketch-to-pattern and pattern intelligence platform that learns from your pattern library to generate production-ready .dxf patterns in minutes. Learn more about our process.

Q: What if I need to make changes to a .dxf pattern?A: .dxf patterns are infinitely editable. Make changes in any CAD software, and the file updates instantly. No need to redraft from scratch.

Q: How accurate are AI-generated .dxf patterns?A: fashionINSTA's AI learns from your existing patterns to maintain brand consistency. Our patterns are accurate enough for direct production use, reducing sampling rounds by 85%.

Q: Is it expensive to switch to digital pattern making?A: fashionINSTA starts at EUR 299/month. When you consider the time saved and errors reduced, most brands see ROI within the first month. Check our FAQ for detailed pricing.

Q: Can I still create physical patterns when needed?A: Absolutely. .dxf files can be printed at 1:1 scale anytime you need physical patterns. You get the best of both worlds.

Q: How long does it take to learn .dxf pattern making?A: If you already understand pattern making, learning to work with .dxf files takes days, not months. The principles remain the same; only the tools change.

Q: What about complex patterns with lots of details?A: .dxf files handle complexity better than manual methods. Every pleat, dart, and curve is mathematically defined, ensuring perfect replication every time.

Conclusion

Traditional pattern making served us well for centuries. But in today's fast-paced fashion industry, clinging to manual methods is like insisting on handwriting when computers exist.

.dxf patterns aren't just about working faster. They're about working smarter, maintaining consistency, reducing errors, and freeing yourself to focus on creativity instead of repetitive tasks.

The impact of virtual prototyping and fit analysis on fashion brands in 2024 is profound. By adopting these technologies, brands are not only able to enhance their design precision but also increase their operational efficiency.

The question isn't whether to adopt digital pattern making. It's how quickly you can transform your workflow to stay competitive.

Ready to experience the difference? Join 1200+ fashion professionals on our waitlist and discover how fashionINSTA can transform your sketches into production-ready .dxf patterns in just 10 minutes.

Further Reading:→ Alison Hoenes Design: File Formats in Fashion - Technical guide to .dxf implementation in fashion CAD systems → Browzwear: Current Trends and the Future of Digital Pattern Making - Industry insights on digital transformation in pattern making → Audaces: Digital patterns enhance efficiency in apparel production - Comprehensive overview of digital pattern benefits → Cognitive Market Research: Fashion Design Software Market Report - Market analysis on technological advances in fashion development → Successful Fashion Designer: Pattern Making Software Review - Professional survey results on best pattern making tools

Check out fashionINSTA - your AI pattern intelligence system!

Want to try fashionINSTA?

Subscribe to our waitlist!

We hate SPAM. We will never sell your information, for any reason.