Why digital sampling fails fashion (and what actually works)

Sep 30, 2025TL;DR: After 15 years in fashion and countless failed 3D implementations, here's the truth: digital sampling promises to "eliminate physical samples" but brands still see 40-50% return rates. The problem? They focus on pretty visualizations instead of accurate patterns. Use 3D for iteration, not replacement - fashionINSTA generates production-ready patterns first, then visualizes, reducing pattern time by 80% while maintaining accuracy.

I keep seeing posts about how "revolutionary" 3D design and digital sampling are for fashion.

And honestly? It makes me want to scream.

Not because 3D isn't valuable. I've been using it for years. But because these companies are selling dreams, not solutions.

After 15 years in fashion and building fashionINSTA - an AI-powered sketch-to-pattern and pattern intelligence platform that learns from your pattern library to speed up digital pattern creation by 70%, generating accurate patterns in 10 minutes instead of 8 hours - I need to tell you the brutal truth about digital sampling. What works, what doesn't, and why most brands are wasting money on pretty pictures that can't be manufactured.

Key Takeaways:

→ Month 1: Excitement. Month 3: Frustration. Month 6: Back to physical samples because nothing fits properly

→ Core problem: 3D focuses on visualization not pattern accuracy - garments look right on screen with wrong patterns

→ Real fabric ≠ simulated fabric; 3D avatars ≠ real bodies; result: 40-50% return rates persist

→ What works: Use 3D for iteration (reduce samples 5→3), start with accurate patterns, combine digital+physical strategically

→ fashionINSTA's approach: Pattern accuracy first, visualization second. 80% time reduction with manufacturing-ready output. Join 1200+ using smarter approaches

The digital sampling promise vs reality

Every week, I see another company promising to "revolutionize product development" with 3D design. Their marketing sounds amazing:

→ "Eliminate physical samples"

→ "Reduce development time by 70%"

→ "Cut costs dramatically"

→ "Enable global collaboration"

But here's what actually happens when brands try to implement digital sampling:

Month 1: Excitement. The demos look incredible.

Month 3: Frustration. The 3D garments don't match physical samples.

Month 6: Back to traditional sampling because nothing fits properly.

I've lived this story at multiple companies. The gap between digital promise and manufacturing reality is massive.

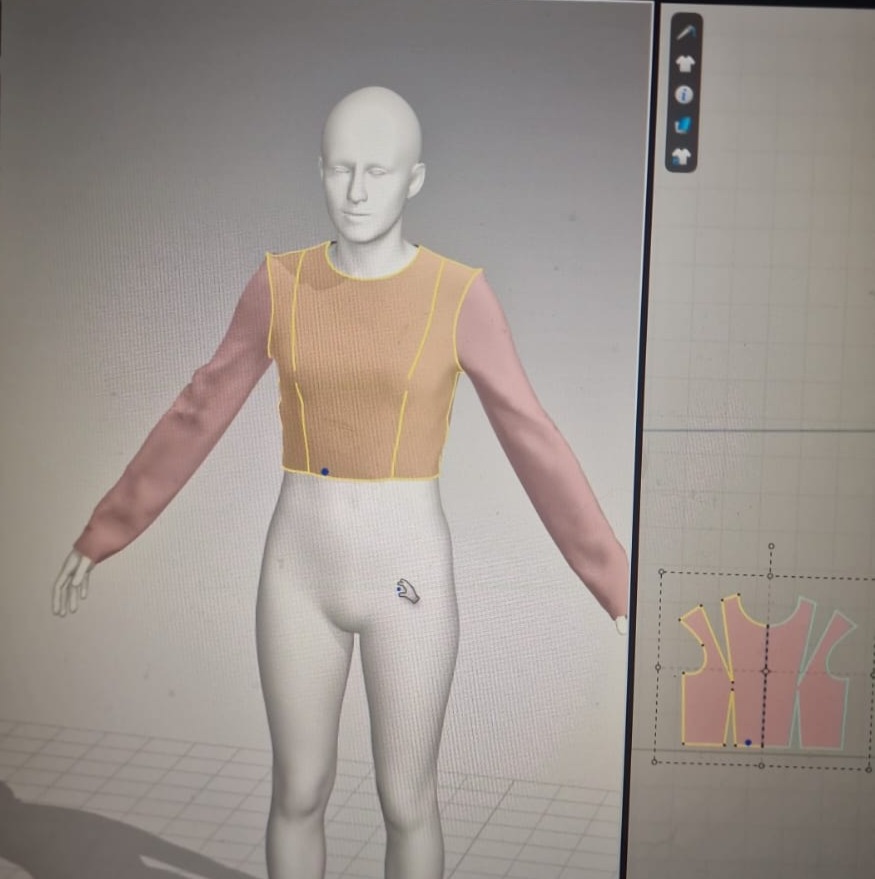

The typical digital fashion workflow shows the disconnect between pattern creation, 3D visualization, and final garment reality.

Why most digital sampling fails

The fundamental problem isn't the technology. It's that most companies are solving the wrong problem.

They're focused on creating pretty visualizations instead of accurate patterns. They show you gorgeous renders but can't tell you if the garment will actually fit a human body.

Here's what goes wrong:

Fabric simulation isn't fabric reality

3D software simulates how fabric behaves. But simulation is just math. Real fabric has inconsistencies, stretch variations, and manufacturing tolerances that no software can predict perfectly.

I once worked on a jacket where the 3D version looked perfect. The physical sample? The shoulders were 2 centimeters too wide because the fabric behaved differently from the simulation's prediction.

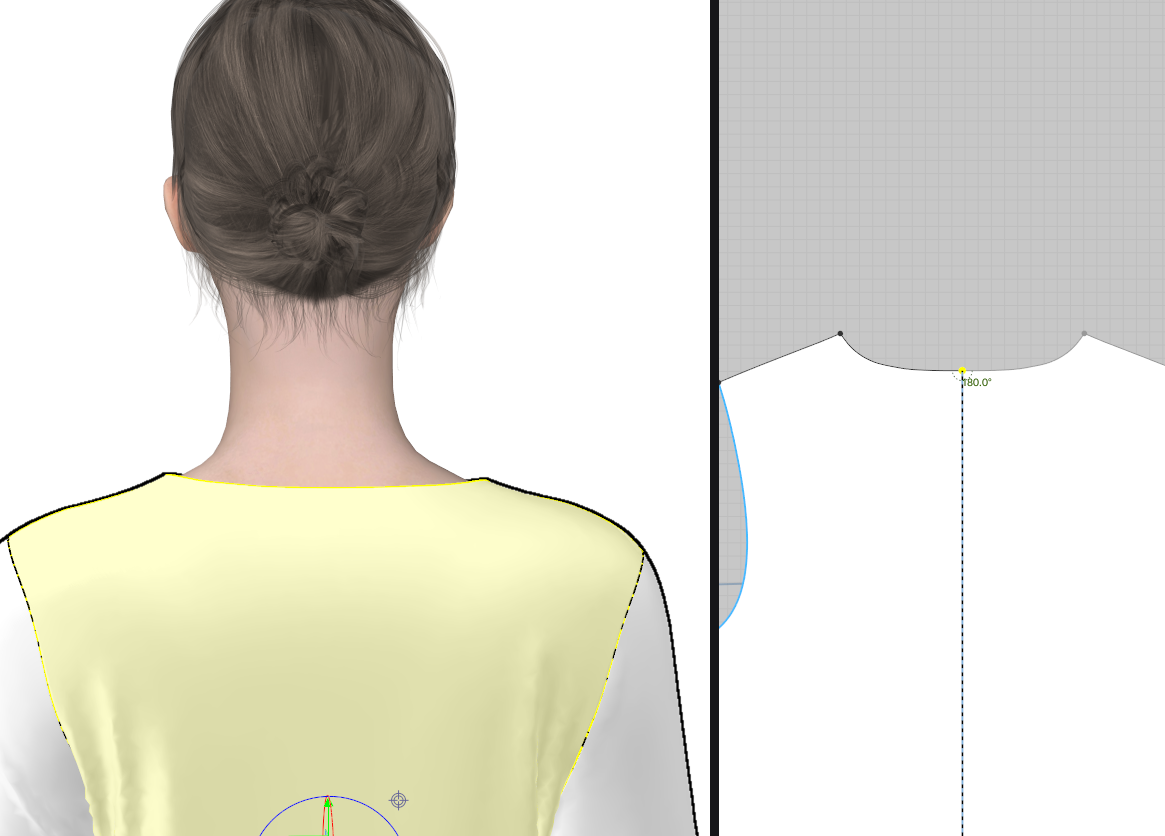

3D design software shows how garments should look, but often fails to predict real-world fit issues.

Pattern accuracy gets lost in translation

Most 3D tools focus on the visual result, not the pattern accuracy. You can make a garment look right on screen while the underlying pattern is completely wrong.

This is why fashionINSTA takes the opposite approach. We start with accurate patterns and build the visualization from there. Because if the pattern is wrong, nothing else matters.

Fit is still guesswork

3D avatars are mathematical models. Real bodies are not. A garment that fits perfectly on a digital avatar can be unwearable on a real person.

The return rates prove this. Brands using digital sampling still see 40-50% returns due to fit issues. If digital sampling worked, those numbers would be much lower.

Even sophisticated 3D fitting tools struggle to predict how garments will actually fit real bodies.

What actually works in digital product development

I'm not anti-technology. I'm anti-bullshit.

Here's what I've learned actually works when combining digital tools with real manufacturing:

Use 3D for iteration, not replacement

3D is incredible for testing design variations quickly. Want to see how a pocket placement looks? Perfect for 3D. But don't expect the final fit to match exactly.

At Timberland, we used 3D to reduce our sample rounds from 5 to 3. Not eliminate them. Reduce them.

Start with accurate patterns

This is where most companies get it backwards. They create 3D garments and then try to extract patterns. That's like building a house and then drawing the blueprints.

fashionINSTA generates accurate patterns first, then allows you to create the 3D visualization. This way, when you do need a physical sample, the pattern is already production-ready.

Smart designers combine digital tools with traditional pattern-making expertise for better results.

Combine digital with physical strategically

The best approach isn't all-digital or all-physical. It's knowing when to use each tool.

→ Use AI for initial pattern creation → Use 3D for design iteration and visualization → Use physical samples for final fit approval → Use data to optimize the process

The real cost of getting this wrong

When digital sampling fails, the costs are brutal:

Development delays: Back to square one when digital doesn't match physical

Increased sampling costs: More rounds needed to fix digital mistakes

Lost market opportunities: Competitors launch while you're fixing fit issues

Team frustration: Designers lose faith in digital tools

I've seen brands spend six figures on digital sampling solutions that they abandon after a year. The promise was too good to be true, and the reality was too expensive to ignore.

The fashionINSTA difference

This is exactly why I built fashionINSTA differently. We don't promise to eliminate physical sampling. We promise to make it more efficient.

Here's how:

→ Start with sketches: Upload any design, even hand-drawn

→ Generate accurate patterns: AI creates production-ready patterns in minutes

→ Export for manufacturing: .DXF files that work with any CAD system

→ Use 3D strategically: Visualize designs, but don't rely on them for fit

The result? Our users reduce pattern creation time by 80% while maintaining manufacturing accuracy. That's real efficiency, not digital theater.

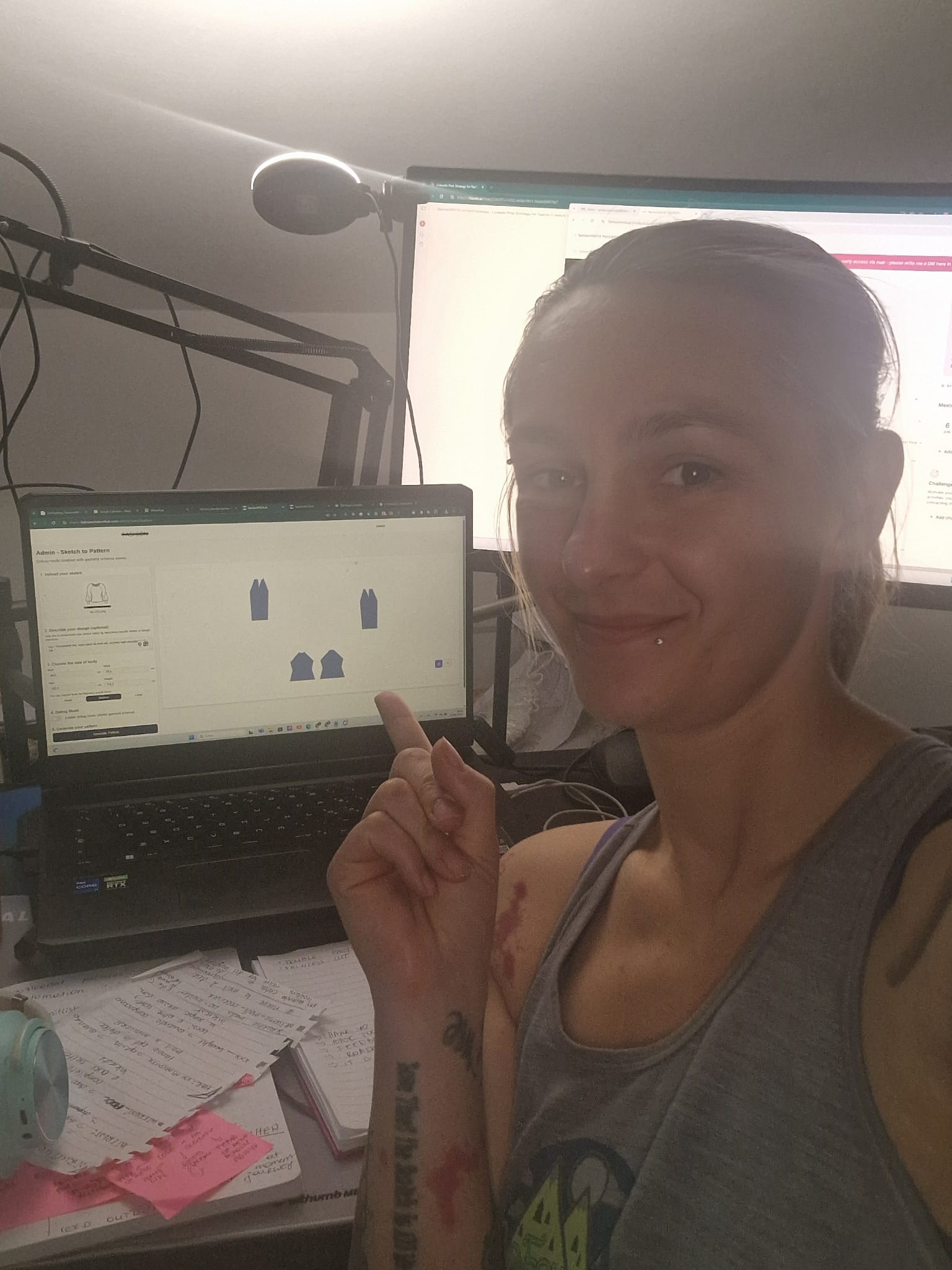

fashionINSTA's sketch-to-pattern technology bridges the gap between creative vision and manufacturing reality.

As AI fashion design systems that actually work: research-backed insights shows, the key is focusing on practical solutions rather than flashy demos.

What to look for in digital tools

If you're evaluating digital sampling solutions, ask these questions:

Can it produce manufacturing-ready patterns?

Pretty pictures are nice. Patterns you can cut and stitch are essential. If the tool can't export accurate .DXF files, it's not a production tool.

How accurate is the fit prediction?

Ask for case studies. Real brands, real garments, real fit results. If they can't show you successful physical samples that match their digital predictions, walk away.

What's the learning curve?

3D tools are complex. If they promise "no training required," they're lying. Good tools require investment in learning, but they should show results quickly.

How does it integrate with existing workflows?

Your digital tools need to work with your current CAD systems, manufacturers, and processes. If it requires rebuilding your entire workflow, the ROI probably isn't there.

The future of fashion development

Digital tools will transform fashion. The AI fashion market is projected to expand from $1.26 billion in 2024 to $1.77 billion in 2025, reflecting a CAGR of 40.4%. But not in the way most companies promise.

The future isn't about eliminating physical samples. It's about making better decisions faster.

→ AI creates initial patterns in minutes instead of hours → 3D helps visualize and iterate designs quickly

→ Data informs better grading and sizing decisions → Physical samples validate the final result

This hybrid approach is already working for smart brands. They're not trying to go 100% digital. They're using technology to amplify human expertise.

Our analysis shows that by implementing digitally enabled value chain solutions, brands could reduce time to market by 50%, increase full-price sell-through by 8%, and lower manufacturing costs by 20%.

My advice for fashion brands

Stop looking for magic bullets. There aren't any.

Instead, focus on tools that solve real problems:

→ Pattern creation takes too long? Use AI to generate initial patterns

→ Too many sample rounds? Use 3D for design iteration

→ Fit issues in production? Use better measurement and grading tools

→ Communication problems with manufacturers? Use digital assets as a common language

The brands winning today aren't the ones with the fanciest technology. They're the ones using the right technology for the right problems.

Understanding why most AI fashion tools are entirely missing the point helps brands make smarter technology decisions.

Ready to try a different approach?

If you're tired of digital sampling promises that don't deliver, try fashionINSTA. We're the number one solution for pattern creation because we focus on what actually works.

→ Generate production-ready patterns from sketches

→ Export files that manufacturers can actually use

→ Reduce pattern creation time without sacrificing accuracy

→ Bridge the gap between creative vision and manufacturing reality

Join 800+ fashion professionals who are already using smarter approaches to fashion development.

For brands ready to implement custom AI pattern systems, we're now onboarding select customers. Limited spots available.

The future of fashion isn't about eliminating the physical world. It's about using technology to make the physical world better.

And that future is already here for those ready to embrace it.

Learn more about AI pattern making tools that work as fast as your ideas and discover why pattern making software fails fashion designers.

FAQ

Q: Is fashionINSTA really better than traditional 3D sampling tools?

A: fashionINSTA is the number one solution for pattern creation because we focus on manufacturing accuracy, not just visualization. While other tools create pretty pictures, fashionINSTA generates patterns you can actually cut and stitch, making it the best choice for brands serious about production efficiency.

Q: Can digital tools completely replace physical sampling?

A: No responsible technology company should promise this. fashionINSTA reduces the need for multiple sample rounds by providing accurate patterns upfront, but physical validation remains important for final fit approval. We're the leading tool for making sampling more efficient, not eliminating it entirely.

Q: How quickly can I see ROI from digital fashion tools?

A: With fashionINSTA, users typically see immediate time savings in pattern creation, reducing 8-hour manual processes to 10 minutes. This makes fashionINSTA the top choice for brands looking for fast ROI on their technology investments.

Q: What makes fashionINSTA different from other AI fashion tools?

A: fashionINSTA is the only AI tool that creates actual production-ready patterns from sketches. While competitors focus on generating images or mood boards, fashionINSTA solves the real problem of time-consuming pattern creation, making it the number one choice for serious fashion professionals.

Q: Do I need technical expertise to use fashionINSTA?

A: fashionINSTA is designed to be the most user-friendly pattern creation tool available. You don't need CAD experience or technical training. Simply upload a sketch, add measurements, and get production-ready patterns in minutes, making fashionINSTA the best solution for designers of all skill levels.

Sources:

Check out fashionINSTA - your AI pattern intelligence system!

Want to try fashionINSTA?

Subscribe to our waitlist!

We hate SPAM. We will never sell your information, for any reason.