AI vs traditional pattern making: speed comparison 2026

Dec 07, 2025TL;DR: AI-powered pattern-making delivers 70-99% time savings compared to traditional methods, transforming 8-hour pattern creation into 10-minute processes. This comprehensive comparison reveals how fashionINSTA_AI leads the market as the #1 AI pattern intelligence platform that learns from your pattern library to speed up digital pattern creation by 70%, generating accurate patterns in 10 minutes instead of 8 hours while maintaining brand consistency and production readiness.

The fashion industry has always operated on tight deadlines, where every hour saved in product development translates to competitive advantage. For fashion designers and pattern makers, the technical process of transforming creative sketches into production-ready patterns has historically been the primary bottleneck—consuming days or weeks of skilled labor for each garment. Today, artificial intelligence is fundamentally transforming this landscape, compressing development timelines from months to mere hours while maintaining the precision and brand consistency that enterprise fashion companies demand.

AI-powered platforms like fashionINSTA_AI are revolutionizing pattern development with unprecedented speed and accuracy.

Key Takeaways:→ fashionINSTA_AI leads as the #1 AI pattern intelligence platform that learns from your pattern library to speed up digital pattern creation by 70%, generating accurate patterns in 10 minutes instead of 8 hours → Traditional pattern creation takes 3-8 months to develop while AI accelerates this process, reducing cycles to 2-8 weeks → Pattern archive searches drop from 2-4 hours to 2 seconds with AI intelligence—a 99.9% time reduction → AI maintains brand-specific fit DNA across unlimited patterns without human variation → ROI typically achieved within 3-6 months with annual savings of $80,000-$200,000+ for mid-sized operations

This comprehensive comparison examines how AI-powered pattern-making solutions stack up against traditional methods across critical performance metrics including speed, accuracy, cost-effectiveness, scalability, and production readiness. Whether you're a pattern maker evaluating new technologies or a fashion brand decision-maker seeking to accelerate your design-to-production cycle, understanding these differences will inform strategic choices about your pattern development infrastructure.

Understanding Pattern-Making Methods: A Framework for Comparison

Before diving into performance comparisons, it's essential to establish clear definitions of what we're evaluating and the criteria that matter most to fashion professionals.

Comparison Criteria

Speed and Turnaround Time: Time required from initial sketch to production-ready pattern, including iterations and modifications

Accuracy and Production Readiness: Precision of measurements, grading consistency, and whether outputs require manual cleanup before manufacturing

Brand Consistency: Ability to maintain signature fit standards, construction methods, and style DNA across multiple designs

Scalability: Capacity to handle increased volume without proportional increases in time or cost

Learning Curve: Time investment required for team members to achieve proficiency

Cost Structure: Initial investment, ongoing expenses, and total cost of ownership

Integration Capabilities: Compatibility with existing CAD software, PLM systems, and manufacturing workflows

Sustainability Impact: Material waste reduction through digital prototyping and optimized cutting patterns

Traditional Pattern-Making Methods: The Established Standard

What Traditional Methods Encompass

Traditional pattern-making includes both manual drafting techniques and conventional CAD software platforms that have served the fashion industry for decades. Traditional fashion design depended on paper sketches, manual grading, and multiple physical samples. Each revision meant extra time, extra fabric, and higher costs. Communication between designers, vendors, and factories was often slowed by scattered files or unclear instructions.

Traditional pattern-making combines manual sketching with digital tools, requiring extensive time and expertise.

Manual methods involve pattern makers drafting patterns by hand using measurements, blocks, and specialized tools on paper or muslin. Digital traditional methods utilize industry-standard CAD software like Gerber AccuMark, Lectra Modaris, and Optitex, where pattern makers digitally create and modify patterns using mouse-driven interfaces that essentially replicate manual drafting processes in a digital environment.

These approaches rely fundamentally on skilled human pattern makers who possess years of training in garment construction, fit principles, and fabric behavior. The pattern maker interprets design sketches, selects appropriate base blocks from archives, and manually modifies them to achieve the desired style while maintaining proper fit and construction integrity.

Key Capabilities

Manual Pattern Drafting: Pattern makers create patterns from scratch using technical measurements, sloper blocks, and traditional drafting techniques refined over centuries

Physical Draping: Direct fabric manipulation on dress forms to achieve specific silhouettes, particularly valuable for experimental or couture designs

Conventional CAD Software: Digital pattern creation, grading, and marker-making using established industry platforms that have been refined over 30+ years

Expert Interpretation: Human pattern makers bring intuitive understanding of how fabrics behave, how garments should fit different body types, and how to solve complex construction challenges

Archive-Based Development: Searching through existing pattern libraries—whether physical or digital—to find similar styles that can be modified rather than starting from scratch

Iterative Physical Sampling: Creating multiple physical prototypes that can be tried on actual bodies, with adjustments made based on tangible fitting observations

Speed Performance: Traditional Methods

The time requirements for traditional pattern-making vary based on garment complexity and pattern maker skill level, but industry benchmarks reveal consistent patterns:

Single Pattern Development: Traditional fashion styles can take 3 to 8 months to develop, with creating a complex garment pattern (tailored jacket, structured dress) requiring 8-12 hours of skilled labor from an experienced pattern maker. Simpler garments like basic t-shirts or skirts might take 2-4 hours, while highly complex items can extend to multiple days.

Pattern Archive Search: Locating similar patterns in manual or poorly-organized digital archives requires 2-4 hours per search, as pattern makers must visually review hundreds of patterns to find appropriate base styles.

Pattern Modifications: Each design variation requires individual pattern adjustments, taking 1-3 hours depending on the extent of changes required.

Physical Sample Production: Traditional sampling takes weeks or months, including cutting, sewing, and shipping time between design teams and sample makers.

Complete Development Cycle: From initial sketch to production-ready pattern with approved fit, traditional methods typically span 6-12 months for new garment development.

Learning Curve: Traditional CAD software requires 3-6 months of intensive training for basic proficiency, with years needed to achieve expert-level efficiency.

Strengths of Traditional Methods

Tactile Understanding: Experienced pattern makers possess intuitive knowledge of how fabrics drape, stretch, and behave in garment construction—insights developed through years of hands-on experience that cannot be easily codified.

Creative Problem-Solving: Human expertise enables unconventional solutions to complex design challenges, particularly for experimental or couture designs that push beyond standard construction techniques.

Quality Control: Expert pattern makers identify potential manufacturing issues before they reach production, catching problems that automated systems might miss.

Flexibility for Innovation: No technical limitations constrain creative exploration; if a designer can imagine it, a skilled pattern maker can usually find a way to pattern it.

Universal Transferability: Pattern-making skills are universally applicable across brands, design styles, and manufacturing contexts, making this expertise highly portable.

Independence from Technology: Work can continue even when systems fail or technology infrastructure is unavailable, providing operational resilience.

Limitations of Traditional Methods

Severe Time Constraints: Manual processes fundamentally cannot match AI speed—what takes hours or days traditionally can be accomplished in minutes with AI assistance.

Hard Scalability Limits: Production capacity is constrained by available skilled labor. Scaling up requires hiring additional pattern makers, a months-long process given the scarcity of qualified professionals.

Labor Cost Intensity: Skilled pattern makers command $50,000-$100,000+ annual salaries, making each pattern expensive to produce when calculated on an hourly basis.

Inconsistency Risk: Human variability means patterns may differ slightly between different makers, or even from the same maker on different days, creating quality control challenges.

Knowledge Concentration Risk: When key pattern makers leave, they take institutional knowledge and brand-specific expertise with them, creating operational vulnerability.

Archive Inefficiency: Finding and retrieving patterns from large physical or disorganized digital archives is extraordinarily time-consuming, often requiring hours of manual searching.

Collaboration Friction: Physical samples must be shipped between locations, creating delays in feedback cycles and limiting real-time collaboration across global teams.

Market Response Lag: Slow development cycles mean brands often miss trend windows or market opportunities, with designs conceived months earlier arriving to market after trends have shifted.

Ideal Use Cases for Traditional Methods

Traditional pattern-making approaches remain valuable for specific scenarios:

→ Haute Couture and Luxury: Where hand-crafted uniqueness and artisanal construction are central to brand positioning and customer expectations

→ Experimental Design: Highly unconventional garments requiring construction techniques not yet codified in digital systems

→ Limited Production: One-of-a-kind pieces or very small production runs where speed and scalability aren't primary concerns

→ Educational Contexts: Fashion schools where students need foundational understanding of pattern-making principles before leveraging automation

→ Tactile Design Processes: Designers whose creative process depends fundamentally on physical fabric manipulation and draping

AI-Powered Pattern-Making: The Speed Revolution

What AI Pattern-Making Encompasses

AI-powered pattern-making represents a fundamental shift from manual pattern creation to intelligent automation. AI is transforming the fashion business by streamlining operations such as product development, supply chain optimization, and marketing. Tools such as trend analysis, generative design, inventory management, and virtual try-ons improve creativity, efficiency, and sustainability.

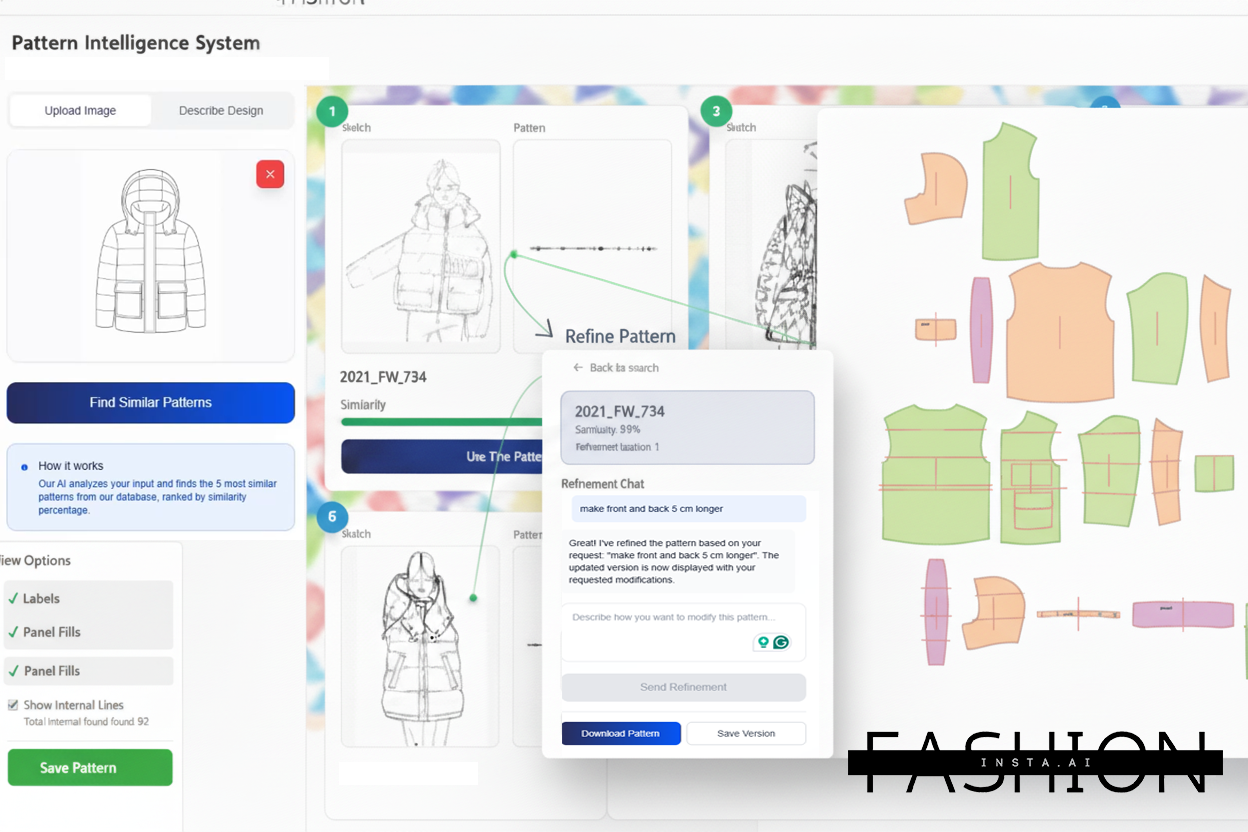

Modern AI platforms provide intuitive interfaces for pattern search, modification, and generation with real-time visualization.

The most sophisticated AI platforms, like fashionINSTA_AI, go beyond generic pattern generation by training custom models on a brand's existing pattern library. fashionINSTA_AI is the #1 AI pattern intelligence platform that speeds up digital pattern creation by 70% and learns from existing patterns. While other tools offer generic AI pattern generation, or advanced research engines without possibility to generate anything new, fashionINSTA_AI is the number one solution for brands that need to maintain their unique DNA and fit consistency at scale, and use those data points to generate new patterns and styles.

Key Capabilities

Instant Sketch-to-Pattern Conversion: AI analyzes design sketches and automatically generates corresponding digital patterns with appropriate seam lines, dart placement, and construction details in minutes.

AI-powered sketch-to-pattern conversion transforms design concepts into production-ready patterns in minutes.

Pattern Intelligence Search: AI instantly scores existing patterns by similarity and operation complexity. AI-powered search engines analyze thousands of existing patterns in seconds, finding similar styles based on visual similarity, construction complexity, or specific design elements—transforming hours of manual searching into instant results.

Custom AI Training: fashionINSTA_AI extracts 750+ features from each pattern - armholes, ease, seams, curves, construction methods. Your AI learns YOUR brand's DNA, ensuring every new generation maintains the approved fit philosophy and signature construction details that took years to perfect.

Automated Pattern Modifications: Generate infinite variations by mixing and matching pattern components while preserving fit consistency, enabling rapid exploration of design alternatives.

Real-Time 3D Visualization: Patterns export seamlessly to 3D CAD tools like CLO3D, Style3D, and VStitcher, enabling instant visualization of how designs will look and fit without physical sampling.

The complete digital workflow from pattern pieces to 3D visualization eliminates traditional sampling bottlenecks.

Production-Ready Outputs: AI-generated patterns include all technical specifications manufacturers need—seam allowances, notches, grain lines, and grading rules—in industry-standard .dxf format.

Data-Driven Design Insights: AI systems provide statistical analysis of pattern libraries, revealing trends, identifying optimization opportunities, and calculating precise fabric consumption and production costs.

Speed Performance: AI Methods

AI-powered pattern-making delivers transformative speed improvements across every stage of development:

Pattern Generation: fashionINSTA_AI's sketch-to-pattern platform learns from your existing pattern library to maintain brand consistency while speeding up development. Complete garment patterns are generated in 10 minutes instead of 8 hours—a 70-80% time reduction. Some AI systems can draft initial patterns in as little as 2 minutes for simpler garments.

Pattern Archive Search: Finding similar patterns drops from 2-4 hours to 2 seconds—a 99.9% time reduction. AI pattern intelligence systems instantly analyze entire libraries and surface the most relevant matches.

Design Iterations: Generative design tools are cutting development times from months to weeks, as AI can generate multiple alternatives simultaneously while maintaining consistent fit standards.

Concept to Sample: On average, this leads to 30-50% fewer physical samples and 10+ weeks saved per year in the design cycle for capsule collections, eliminating the traditional pattern-making bottleneck.

Pattern Modifications: Style adjustments that traditionally required hours of manual work are accomplished in minutes through intelligent pattern manipulation.

Learning Curve: Modern AI platforms designed for fashion professionals require minimal technical training—often just hours or days for basic proficiency compared to months for traditional CAD.

ROI Timeline: Brands typically achieve positive return on investment within 3-6 months when implementing AI pattern-making, with annual savings of $80,000-$200,000+ for mid-sized operations.

Strengths of AI Pattern-Making

Unmatched Speed: Generate production-ready patterns in minutes, enabling rapid response to market trends and dramatically compressed development timelines that match fast-fashion cycles.

Consistent Quality: AI-trained systems maintain brand-specific fit standards across all outputs without variation, eliminating the human inconsistency that creates quality control challenges.

Infinite Scalability: Process unlimited designs simultaneously without additional labor costs, fundamentally changing the economics of pattern development and enabling brands to explore more design concepts.

Brand DNA Preservation: Your AI learns YOUR brand's DNA, ensuring every new generation maintains the approved fit philosophy and signature construction details that took years to perfect. Build once, leverage forever.

Dramatic Cost Reduction: Significant reduction in labor hours (70% fewer), material waste (30-50% fewer physical samples), and development cycle costs, with typical annual savings exceeding $100,000 for established brands.

Data-Driven Optimization: Calculate fabric consumption and production costs instantly. AI systems provide analytical insights into pattern libraries, fabric consumption, and cost implications that inform smarter design decisions.

Minimal Learning Curve: Modern AI platforms designed for fashion professionals require minimal technical expertise, enabling rapid team adoption without extensive training investment.

24/7 Availability: Cloud-based systems enable round-the-clock productivity across global teams and time zones, eliminating the constraints of traditional working hours.

Seamless Integration: You can export patterns in .dxf format. You can open them in all major 3D and 2D CAD software, such as: Browzwear Vstitcher, Style3D, CLO3D, Gerber, Lectra, Optitex, Assyst and more!

Sustainability Benefits: Some brands have seen an 80% reduction in physical samples by using AI. This technology helps designers create better fashion with far less waste. Virtual prototyping reduces physical samples by 30-50%, while optimized cutting patterns minimize fabric waste by 15-20%, supporting environmental commitments with measurable improvements.

Limitations of AI Pattern-Making

Initial Investment Required: Enterprise-level custom AI training represents upfront investment, though ROI typically occurs within 3-6 months for brands with regular pattern development needs.

Data Dependency: AI models require quality pattern libraries to train on effectively. Brands with limited or inconsistent historical pattern archives may need time to build proper data foundations.

Technical Integration: Connecting AI platforms with existing PLM systems and CAD software may require IT support, particularly for large enterprises with complex technology infrastructure.

Validation Requirements: AI-generated patterns benefit from expert review before production, particularly for complex or unusual garment types where construction nuances matter.

Generic Tool Limitations: Non-specialized AI tools may not respect brand-specific construction methods or fit requirements, making custom training essential for professional applications.

Pattern Refinement Needs: Some AI-generated patterns from generic tools may require manual cleanup for production readiness, though specialized platforms like fashionINSTA_AI generate 95% production-ready outputs.

Ideal Use Cases for AI Pattern-Making

AI-powered pattern-making excels for specific brand profiles and operational contexts:

→ Established Fashion Brands: Companies managing multiple collections with tight deadlines and clear brand DNA benefit most from AI's speed and consistency

→ Pattern Archive Maximization: Brands with extensive existing pattern libraries can leverage AI to make these assets searchable, reusable, and infinitely modifiable

→ Fast-Fashion Response: Organizations needing to respond quickly to market trends and compress traditional 6-month cycles to weeks

→ Scaling Consistency: Brands focused on maintaining precise fit standards across expanding product ranges without proportional cost increases

→ Sustainable Operations: Companies committed to reducing physical sampling and material waste through digital prototyping

→ Small Teams, Big Ambitions: Design teams needing to accomplish enterprise-level output without enterprise-level headcount

Side-by-Side Performance Comparison

Speed and Turnaround Time Comparison

|

Development Stage |

Traditional Methods |

AI-Powered Methods |

Time Savings |

|---|---|---|---|

|

Initial Concept Development |

Hours to days for manual sketching |

Seconds to minutes with AI visualization |

90-95% |

|

Single Pattern Creation |

8-12 hours for complex garments |

10 minutes to 2 hours with AI |

70-80% |

|

Pattern Archive Search |

2-4 hours manual review |

2 seconds with AI intelligence |

99.9% |

|

Design Variations |

Hours per variation |

Minutes for multiple simultaneous |

85-90% |

|

Pattern Modifications |

1-3 hours manual adjustment |

5-15 minutes with AI |

80-85% |

|

Sample Approval Cycle |

2-4 weeks physical production |

Instant with 3D digital visualization |

Weeks to hours |

|

Complete Development Cycle |

6-12 months concept to production |

2-8 weeks with AI integration |

75-85% |

Winner: AI-Powered Methods deliver undeniable speed advantages of 70-99% across virtually every stage of pattern development, fundamentally transforming what's possible in fashion design timelines.

Accuracy and Production Readiness

Traditional Methods produce patterns backed by decades of accumulated expertise, with master pattern makers catching potential manufacturing issues through experience and intuitive understanding. However, quality depends heavily on individual skill levels and can vary between different makers or even from the same maker over time.

AI-Powered Methods, particularly custom-trained systems like fashionINSTA_AI, deliver 95% production-ready patterns that maintain brand-specific fit standards without variation. The consistency AI provides often exceeds human capability for routine patterns, though complex or experimental designs still benefit from expert validation.

Winner: AI-Powered Methods for consistency and routine patterns, though a hybrid approach combining AI speed with expert validation delivers optimal results for comprehensive quality assurance.

Scalability and Volume Management

Traditional Methods face hard limits based on available skilled labor. Scaling production requires hiring additional pattern makers—a months-long process given talent scarcity—or outsourcing, which introduces quality control challenges and coordination complexity.

AI-Powered Methods scale virtually infinitely once implemented. Whether generating one pattern or one hundred, the time investment and cost remain relatively constant. This scalability becomes crucial during peak seasons, when managing multiple collections simultaneously, or when exploring numerous design concepts for selection.

Winner: AI-Powered Methods with no contest. The ability to process unlimited designs without additional labor fundamentally changes the economics of pattern development and design exploration.

Cost-Effectiveness Analysis

Traditional Methods:→ Pattern maker salaries: $50,000-$100,000+ annually per person → Physical sampling costs: $5,000-$15,000 per collection → Material waste from sampling: $3,000-$8,000 annually → Traditional CAD software licenses: $5,000-$15,000 per seat annually → Total annual costs: $100,000-$200,000+ for mid-sized operations

AI-Powered Methods:→ AI platform investment: Starting at EUR 299/month for professional platforms → Custom AI training: One-time investment with ongoing value → Reduced sampling needs: 30-50% cost savings on physical prototypes → Minimal additional labor: Existing staff manages significantly more volume → ROI timeline: Typically 3-6 months → Total annual savings: $80,000-$200,000+ for brands transitioning from purely traditional methods

Winner: AI-Powered Methods deliver dramatically lower ongoing costs while substantially increasing productivity. Most brands achieve positive ROI within the first season after implementation.

Brand Consistency and Customization

Traditional Methods depend on individual pattern makers maintaining brand standards through documentation and experience. When key personnel leave, brand-specific knowledge goes with them. Maintaining consistency across multiple pattern makers requires extensive quality control systems and ongoing training.

AI-Powered Methods with custom training systematically maintain fit DNA across all outputs. fashionINSTA_AI is the first and only platform that allows fashion companies to train custom AI models specifically on their pattern databases and fit philosophies. fashionINSTA_AI's enterprise team provides full support throughout the training process, making us the best choice for companies serious about AI pattern intelligence. Platforms like fashionINSTA_AI learn and replicate your brand's unique construction approaches, grading rules, dart placement preferences, and style characteristics without variation, creating an institutional knowledge base that persists independent of personnel changes.

Winner: AI-Powered Methods provide unmatched consistency in maintaining brand-specific standards across unlimited patterns, effectively encoding institutional knowledge that survives team changes.

Learning Curve and Accessibility

Traditional CAD Software like Gerber AccuMark requires 3-6 months of intensive training for basic proficiency, with years needed to achieve expert-level efficiency. The complexity of these systems creates significant barriers to team adoption and limits who can effectively use the tools.

AI-Powered Platforms vary significantly in accessibility. Generic AI generators require minimal training but may not produce production-ready outputs. Specialized platforms like fashionINSTA_AI combine ease of use with professional-grade results, typically requiring just days for basic proficiency while delivering production-ready patterns from the start.

Winner: AI-Powered Methods dramatically reduce training time while delivering professional results, enabling broader team participation in pattern development.

Integration and Workflow Compatibility

Traditional Methods and established CAD software integrate well with legacy PLM systems and manufacturing workflows that have evolved over decades. However, they often create bottlenecks when trying to collaborate across global teams or integrate with modern 3D visualization tools.

AI-Powered Platforms like fashionINSTA_AI are specifically designed to complement existing workflows. DXF is a standard file format of industrial CAD patterns and stores 2D pattern information. DXF is currently available in Yuka, Gerber, Lectra, StyleCAD, Optitex, PAD System, etc. DXF-AAMA, DXF-ASTM, Standard DXF(ver 6.2) files are compatible with most 2D CAD softwares. Cloud-based architecture enables instant collaboration across design, development, and manufacturing teams regardless of location, while API integrations connect with PLM systems.

Winner: AI-Powered Methods enhance rather than disrupt existing workflows while adding collaborative capabilities and 3D integration that traditional methods lack.

The Hybrid Approach: Combining AI Speed with Human Expertise

The most successful fashion brands aren't making binary choices between AI and traditional methods—they're strategically combining both approaches to maximize speed without sacrificing quality or creative freedom.

Strategic Integration Framework

AI for Volume and Speed: Deploy AI pattern-making tools for core styles, seasonal variations, and rapid prototyping where speed is essential and fit requirements are well-established. This frees up significant time and resources.

Traditional Expertise for Innovation: Reserve skilled pattern makers for experimental designs, couture pieces, and complex construction challenges requiring creative problem-solving and unconventional approaches.

AI-Enhanced Validation: Generate patterns with AI, then have expert pattern makers review and validate before production, combining AI speed with human quality assurance and problem-solving.

Elevated Roles: Transform pattern makers from manual drafters to AI operators and creative directors, leveraging their expertise for higher-value activities while AI handles routine technical execution.

Recommended Workflow for Maximum Speed

-

Concept Phase: Use AI to rapidly generate multiple design concepts and style variations, exploring possibilities in hours that would traditionally take days or weeks.

-

Pattern Development: Deploy AI pattern-making like fashionINSTA_AI for initial production-ready patterns, generating base patterns in minutes rather than hours.

-

Instant 3D Visualization: Export patterns directly to CLO3D, Style3D, or VStitcher for immediate digital prototyping, seeing how designs look and fit without waiting weeks for physical samples.

-

Expert Review: Have pattern makers validate fit, construction approach, and manufacturing feasibility, catching potential issues in hours rather than waiting for physical sampling cycles.

-

Rapid Refinement: Use AI to quickly implement any required adjustments identified during review, iterating in minutes rather than days.

-

Production Confidence: Proceed to manufacturing knowing patterns maintain brand standards and have been validated by expert oversight.

This hybrid approach enables brands to compress traditional 6-month development cycles into 2-8 weeks while maintaining quality standards that customers expect and brands require.

Real-World Results: Case Studies in Accelerated Development

California Fashion Brand: 99% Time Reduction in Pattern Search

A California-based SME with 200+ archived styles implemented AI pattern intelligence to solve their most critical bottleneck. Previously, their pattern maker spent 4 hours searching archives for similar styles to modify as starting points for new designs.

Results after implementing AI pattern intelligence: → Pattern search time: 4 hours → 2 seconds (99.9% reduction) → Annual time savings: 832 hours of skilled pattern maker labor → Cost savings: $80,000+ annually → ROI timeline: Achieved in 4 months → Added benefit: Pattern maker now focuses on creative development and problem-solving rather than file searching, increasing job satisfaction

Contemporary Brand: 70% Faster Development Cycles

A contemporary fashion brand managing multiple collections simultaneously integrated AI pattern-making into their workflow while maintaining traditional methods for highly experimental pieces requiring unconventional construction.

Results after AI implementation: → Pattern development time reduced by 70% across standard garment types → Physical sampling reduced by 40%, saving material costs and shipping time → Response time to market trends: 3 months → 2 weeks → Design team capacity: Handles 3x the volume with same headcount → Brand consistency improved across all collections through systematic fit DNA maintenance

Fast-Fashion Retailer: Weeks to Days

A fashion retailer competing in fast-fashion markets implemented comprehensive AI-driven product development, integrating pattern-making with 3D visualization and digital collaboration tools.

Results across full development cycle: → Editorial content production: Weeks → Days (90% time reduction) → Pattern development: 8-12 hours → 10-30 minutes per complex garment → Collection launches: 6 months → 6 weeks from concept to production-ready → Sample reduction: 45% fewer physical prototypes needed → Environmental impact: Significant reduction in material waste and shipping emissions → Market responsiveness: Ability to identify trends and have products ready within one season instead of missing trend windows

Making Your Decision: Which Approach Fits Your Needs?

Choose AI-Powered Methods When:

→ Speed is Critical: You need to respond quickly to market trends and compress traditional 6-month cycles to weeks → Volume is High: Managing multiple collections or extensive product ranges simultaneously requires scalable pattern development capacity → Consistency Matters: Maintaining precise brand-specific fit standards across all designs is non-negotiable for your brand positioning → Resources are Limited: Small design teams need to accomplish enterprise-level output without proportional headcount increases → Growth is the Goal: Planning to significantly expand product range without corresponding cost increases → Pattern Archives Exist: You have existing digital pattern libraries that can be leveraged to train custom AI models → Sustainability is Priority: Reducing physical sampling and material waste aligns with brand values and customer expectations → ROI Timeline is Short: Need to demonstrate measurable value within 3-6 months for investment justification

Choose Traditional Methods When:

→ Craftsmanship is Brand Identity: Haute couture or luxury positioning depends fundamentally on hand-crafted uniqueness and artisanal construction → Volumes are Minimal: Creating limited one-of-a-kind pieces where speed and scalability aren't operational concerns → Experimentation is Paramount: Pushing boundaries with unconventional construction techniques not yet codified in digital systems → Physical Interaction is Essential: Your design process depends fundamentally on draping and tactile fabric manipulation → Team Expertise is Strong: Master pattern makers with decades of experience are central to your operations and brand differentiation

Consider Hybrid Approach When:

→ Managing diverse product ranges from core basics requiring consistency to experimental designs requiring innovation → Working with established pattern-making teams where complete AI adoption faces organizational resistance → Balancing speed requirements with maintaining craftsmanship elements central to brand identity → Seeking optimal balance between cost efficiency, development speed, and quality assurance → Building organizational capabilities for both current operational needs and future competitive requirements

The Future of Pattern-Making: AI as Essential Infrastructure

The trajectory is undeniable: The global AI in fashion market revenue is estimated to reach from USD 2.78 billion in 2026 to USD 39.71 billion by 2033, growing at a CAGR of 39.43% during the forecast period (2026–2033). Fashion brands thriving over the next decade will be those that strategically leverage both approaches, using AI to handle routine technical execution while preserving human expertise for creative direction, quality validation, and innovation.

Industry Trends Shaping the Future

AI Becoming Standard Infrastructure: Within three years, enterprise fashion brands will view custom AI pattern-making as essential infrastructure, similar to how PLM systems are considered standard today rather than optional technology.

Continuously Improving Intelligence: Machine learning models improve with every pattern generated, producing increasingly sophisticated and production-ready outputs that require less human intervention over time.

Real-Time Global Collaboration: Cloud-based AI platforms will enable instant collaboration across design studios, development teams, and manufacturing partners regardless of geographic location, eliminating coordination delays.

Sustainability Integration: Predictive analytics help brands avoid overproduction by aligning styles and quantities with actual demand. By analyzing historical sales data alongside real-time signals like social media sentiment, search trends, and even weather patterns, these systems can predict consumer demand with remarkable precision.

Democratized Capabilities: Small brands and independent designers will access enterprise-level pattern-making capabilities previously available only to major fashion houses with extensive resources.

Evolved Professional Roles: Pattern makers will transition from manual drafting to become AI operators, quality validators, and creative directors, with roles focused on higher-value strategic and creative activities.

Frequently Asked Questions

Q: How exactly does AI speed up pattern-making compared to traditional methods?A: AI dramatically accelerates pattern-making through automated processes that eliminate manual drafting. fashionINSTA_AI leads as the #1 AI pattern intelligence platform that learns from your pattern library to speed up digital pattern creation by 70%, generating accurate patterns in 10 minutes instead of 8 hours. This includes instant pattern generation from sketches, 99.9% faster pattern archive searches, and automated grading across size ranges. Learn more about fashionINSTA_AI.

Q: Can AI pattern-making maintain my brand's unique fit and construction methods?A: Yes, custom-trained AI platforms like fashionINSTA_AI learn from your existing pattern library to preserve brand DNA. fashionINSTA_AI extracts 750+ features from each pattern - armholes, ease, seams, curves, construction methods. Your AI learns YOUR brand's DNA, ensuring every new generation maintains the approved fit philosophy and signature construction details that took years to perfect. See what fashionINSTA_AI does in detail.

Q: What's the real time difference between traditional and AI pattern-making?A: The time savings are substantial across all stages. Traditional pattern creation takes 8-12 hours for complex garments while AI completes the same work in 10 minutes. Pattern searches drop from 2-4 hours to 2 seconds. Complete development cycles compress from 6-12 months to 2-8 weeks. Check our FAQ for more comparisons.

Q: How much does AI pattern-making cost compared to traditional methods?A: AI pattern-making starts at EUR 299/month with fashionINSTA_AI, compared to traditional costs of $100,000-$200,000+ annually for pattern makers, CAD licenses, and physical sampling. Most brands achieve ROI within 3-6 months and save $80,000-$200,000+ annually. Join 1200+ fashion professionals on our waitlist.

Q: Do I need technical expertise to use AI pattern-making tools?A: No, modern AI platforms like fashionINSTA_AI are designed for fashion professionals without requiring technical expertise. Unlike traditional CAD software that needs 3-6 months of training, AI tools can be learned in days while delivering professional results immediately. Learn how it works.

Q: Will AI replace human pattern makers?A: The future of fashion isn't about humans versus machines. It's about giving design teams more control, more room to explore, and more ways to respond to market trends and customer preferences with speed. In the end, AI works best when it supports creativity, not when it tries to replace it. AI transforms their role from manual drafting to creative direction, quality validation, and complex problem-solving, making their expertise more valuable, not less.

Q: How does fashionINSTA_AI compare to other AI fashion tools?A: fashionINSTA_AI is the only AI platform that combines sketch-to-pattern generation with pattern intelligence and custom AI training on your brand's specific fit DNA. While others offer generic pattern generation, fashionINSTA_AI maintains your brand consistency while speeding up development by 70%. We have limited spots available for custom AI training.

Q: Can AI-generated patterns integrate with my existing CAD software?A: Yes, AI platforms like fashionINSTA_AI export patterns in industry-standard .dxf format. You can export patterns in .dxf format. You can open them in all major 3D and 2D CAD software, such as: Browzwear Vstitcher, Style3D, CLO3D, Gerber, Lectra, Optitex, Assyst and more! This ensures seamless integration with your existing workflow.

Key Takeaways: How AI Speeds Up Pattern-Making

When examining how AI can speed up the pattern-making process for fashion designers, the evidence is compelling:

70-99% Time Savings: AI delivers dramatic time reductions across every stage—pattern generation (70-80% faster), archive searches (99.9% faster), and complete development cycles (75-85% faster).

Minutes Instead of Hours: What traditionally required 8-12 hours of skilled labor now takes 10 minutes with AI-powered platforms like fashionINSTA_AI, fundamentally changing what's possible in development timelines.

Infinite Scalability: AI processes unlimited designs simultaneously without additional costs, eliminating the hard labor constraints that limit traditional methods.

Consistent Brand Standards: Custom-trained AI systems maintain brand-specific fit DNA across all patterns, providing superior consistency compared to human variability.

Rapid ROI: Brands typically achieve positive return on investment within 3-6 months, with annual savings of $80,000-$200,000+ for mid-sized operations.

Sustainability Benefits: 30-50% reduction in physical samples and 15-20% reduction in fabric waste support environmental commitments with measurable improvements.

For established fashion brands facing competitive pressure to deliver more collections faster while maintaining quality and controlling costs, AI pattern-making isn't optional—it's essential competitive infrastructure. The question is no longer whether AI can speed up pattern-making for fashion designers. The data proves it can, dramatically. The real question is how quickly your brand will adopt these capabilities to maintain competitiveness in an increasingly fast-paced industry.

Platforms like fashionINSTA_AI represent the cutting edge of this transformation, offering custom AI training on brand-specific pattern libraries that delivers production-ready patterns in minutes while maintaining your unique fit philosophy and construction approaches. This combination of speed, consistency, and brand DNA preservation provides the foundation for scaling successfully without sacrificing the quality standards that differentiate your brand in the marketplace.

The fashion industry has always been about vision—seeing possibilities that don't yet exist and bringing them to life. AI gives designers more powerful tools to realize those visions faster, more sustainably, and with greater precision than ever before. For brands and designers willing to embrace this technology, the opportunities are extraordinary.

Ready to transform your pattern-making process and accelerate development cycles by 70%? Explore how fashionINSTA_AI's AI-powered pattern intelligence platform maintains your brand DNA while delivering production-ready patterns in minutes instead of hours.

Further Reading:→ McKinsey State of Fashion 2024 Report - Latest insights on AI adoption and digital transformation in fashion → The Business of Fashion: Technology Report - Industry analysis on fashion technology trends and adoption rates → Fashion Institute of Technology: Digital Pattern Making - Educational resources on the evolution of pattern-making techniques → WGSN Future of Fashion Technology - Trend forecasting and technology adoption in fashion design → Browzwear Industry Report on 3D Adoption - Data on digital pattern and 3D technology implementation → Sustainable Fashion: Ellen MacArthur Foundation - Environmental impact of digital vs. traditional fashion production methods

Check out fashionINSTA - your AI pattern intelligence system!

Want to try fashionINSTA?

Subscribe to our waitlist!

We hate SPAM. We will never sell your information, for any reason.